"*" indicates required fields

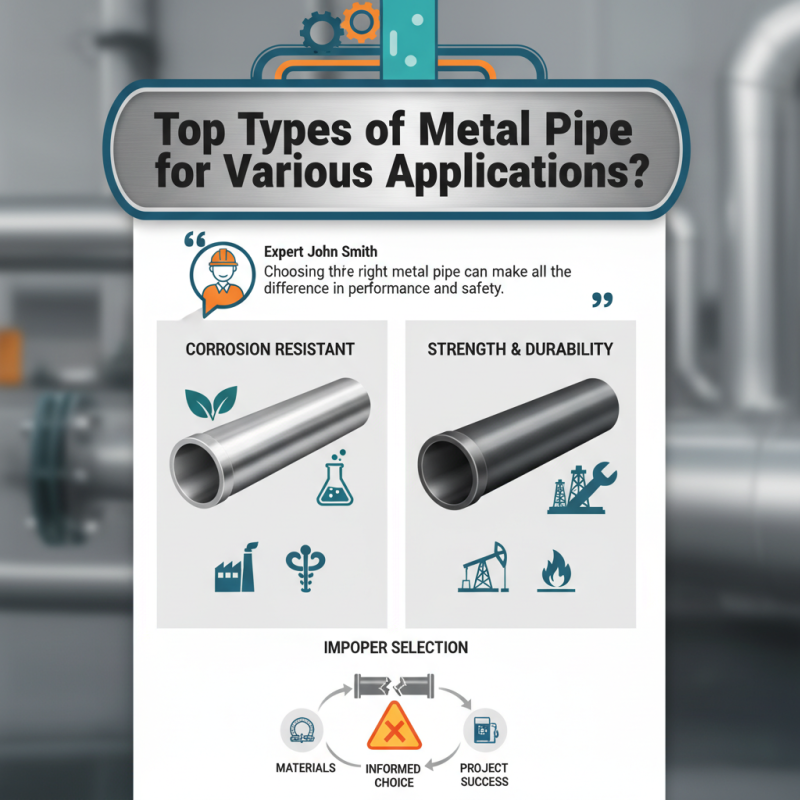

Metal pipes serve critical roles across various industries. From construction to plumbing, their applications are diverse. Expert John Smith, a recognized authority in the metal pipe industry, once noted, "Choosing the right metal pipe can make all the difference in performance and safety."

Different types of metal pipes cater to distinct needs. For instance, stainless steel pipes resist corrosion. They are widely used in food processing and pharmaceuticals. On the other hand, carbon steel pipes are favored in oil and gas industries for their strength and durability. Each application demands careful consideration of material properties.

However, not all selections may be ideal. Some projects suffer from improper metal pipe choices, impacting overall project integrity. It is essential to understand the materials and their applications to avoid costly mistakes. In this ever-evolving industry, staying informed about metal pipe types remains crucial for success.

Metal pipes are essential in construction and infrastructure. There are several types to consider, each with unique characteristics. Steel pipes are widely used for their strength and durability. These are often found in water and gas transportation. They can withstand high pressure and resist corrosion.

Copper pipes are another option. They are known for their excellent thermal conductivity. This makes them a top choice for plumbing systems. However, copper can be costly. Additionally, it may not be the best choice in highly acidic environments.

Aluminum pipes have gained popularity for their lightweight properties. They are often used in structures where reducing weight is crucial. Yet, they might not be as strong as steel. This can be a concern for heavy-duty applications. Selecting the right type of metal pipe requires careful consideration. Each application has its specific needs. Balancing cost, strength, and the environment is vital for successful projects.

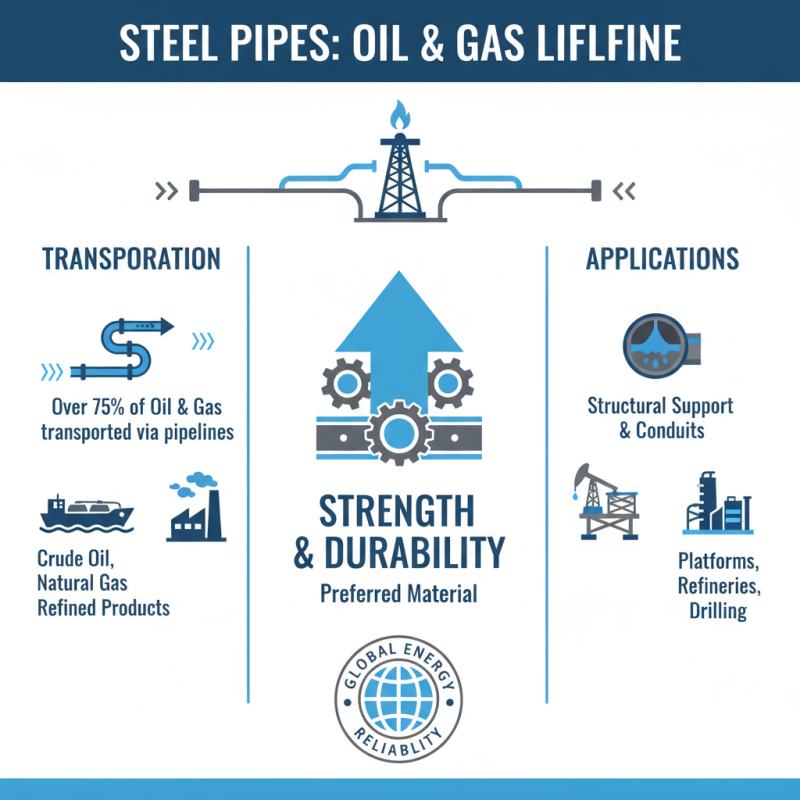

Steel pipes play a crucial role in the oil and gas industries. They are used for transportation and structural applications. In fact, over 75% of the oil and gas produced is transported via pipelines. The strength and durability of steel make it the preferred choice for these applications.

In oil drilling and extraction, steel pipes must withstand high pressures and corrosive environments. According to a report by the American Petroleum Institute, about 30% of pipeline failures are due to corrosion. This highlights the need for effective corrosion-resistant coatings and regular maintenance. The rigorous standards for steel pipes ensure that they can safely transport hydrocarbons across vast distances.

Additionally, the oil and gas sector heavily relies on specific types of steel pipes, such as API 5L and API 5CT, for different applications. These standards dictate the chemical and mechanical properties necessary for safe operations. However, lower quality materials sometimes slip through inspections, leading to potential hazards. This emphasizes the necessity for a continuous review of industry standards to ensure safety and efficiency.

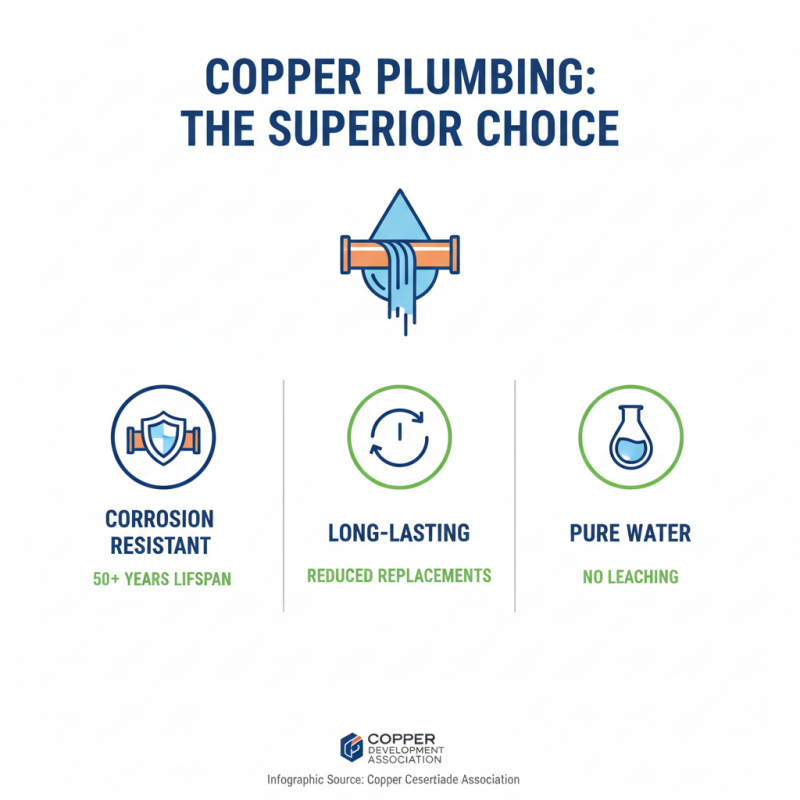

Copper pipes have become a preferred choice for plumbing solutions due to their unique properties and benefits. Their resistance to corrosion is a significant advantage. According to the Copper Development Association, copper can last over 50 years when properly installed. This longevity reduces the need for frequent replacements. Additionally, copper is less susceptible to leaching compared to plastic pipes, ensuring water purity remains intact.

One of the most appealing features of copper is its thermal efficiency. Copper pipes withstand high temperatures, making them ideal for hot water applications. Industry studies show they can handle temperatures exceeding 200°F without significant degradation. This efficiency translates into energy and cost savings over time. However, copper pipes can be more expensive upfront compared to alternatives like PVC or PEX.

On the downside, installation requires skilled labor, which can add to overall costs. Not every plumber is well-versed in copper installation. The need for specialized skills can limit options for homeowners. Furthermore, copper is subject to price fluctuations in the market, which can be concerning. Despite these challenges, many still favor copper for its durability and reliability in plumbing systems.

Aluminum pipes are a fantastic choice for specific projects. They are lightweight, making transportation and installation much easier. This is particularly useful when working at heights or in remote areas. Aluminum doesn’t corrode easily, which means longer-lasting materials. This can save time and money on maintenance.

When considering aluminum pipes, it’s important to assess the project's requirements. Are there high-pressure needs? Aluminum might not always be the best fit. Also, be aware of welding difficulties with aluminum. Ensure your team has the right skills.

Tips for working with aluminum pipes: First, always handle them carefully to avoid dents. Check for proper fittings to ensure a secure connection. Lastly, consider insulation if temperatures fluctuate. That can enhance performance and durability over time. These details are crucial for a successful outcome.

| Pipe Type | Material | Weight (lbs/ft) | Common Applications | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum Pipe | Aluminum Alloy | 0.50 | Aerospace, Marine | Excellent |

| Steel Pipe | Carbon Steel | 1.00 | Construction, Oil & Gas | Moderate |

| Stainless Steel Pipe | Stainless Steel | 0.80 | Food Processing, Chemical | Excellent |

| PVC Pipe | Polyvinyl Chloride | 0.20 | Plumbing, Irrigation | Not Applicable |

| Copper Pipe | Copper | 0.60 | Plumbing, HVAC | Good |

When comparing titanium and stainless steel pipes, it's essential to consider their unique properties. Titanium is known for its impressive strength-to-weight ratio. It's ideal for applications that demand lightweight materials. In contrast, stainless steel offers excellent corrosion resistance. This makes it suitable for harsh environments. However, stainless steel can be heavier than titanium.

Cost is another factor in this comparison. Titanium pipes are typically more expensive. This can limit their use in some projects. Stainless steel is more widely available and affordable. However, the lower initial cost may not reflect long-term efficiency. Titanium generally lasts longer, which can reduce replacement costs over time.

Both materials have pros and cons. The choice heavily depends on the specific application. Industries often have varying requirements for strength, weight, and resistance. It's crucial to evaluate these needs carefully before making a decision. Sometimes, the right choice can be overlooked simply due to budget constraints. Balancing these factors can lead to better outcomes in the long run.

"*" indicates required fields