"*" indicates required fields

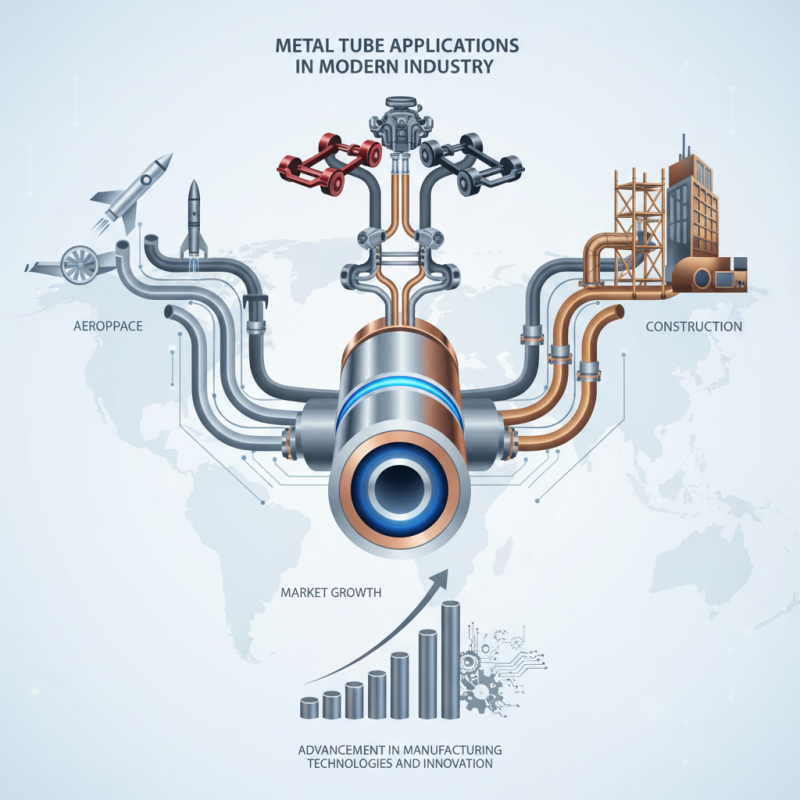

Metal tubes are an essential component in modern industrial applications, serving a wide range of purposes across various sectors. Comprising materials such as stainless steel, aluminum, and titanium, these tubes exhibit remarkable strength, durability, and resistance to corrosion, making them ideal for applications in industries like aerospace, automotive, and construction. According to a report by MarketsandMarkets, the global metal tubing market is projected to reach USD 150 billion by 2025, indicating a robust demand driven by advancements in manufacturing technologies and increasing infrastructure development.

In the aerospace sector, metal tubes are critical in the fabrication of components that require both lightweight properties and high structural integrity. Similarly, the automotive industry relies on metal tubes for fuel lines, exhaust systems, and chassis components, reflecting their versatility and importance. Furthermore, the construction industry utilizes metal tubes in scaffolding, plumbing, and HVAC systems, with the global construction market expected to expand significantly in the coming years. This growth underscores the integral role that metal tubes play in facilitating innovation and efficiency across industrial processes. As technology continues to evolve, the applications and demands for metal tubes are set to diversify, highlighting their indispensable nature in modern industry.

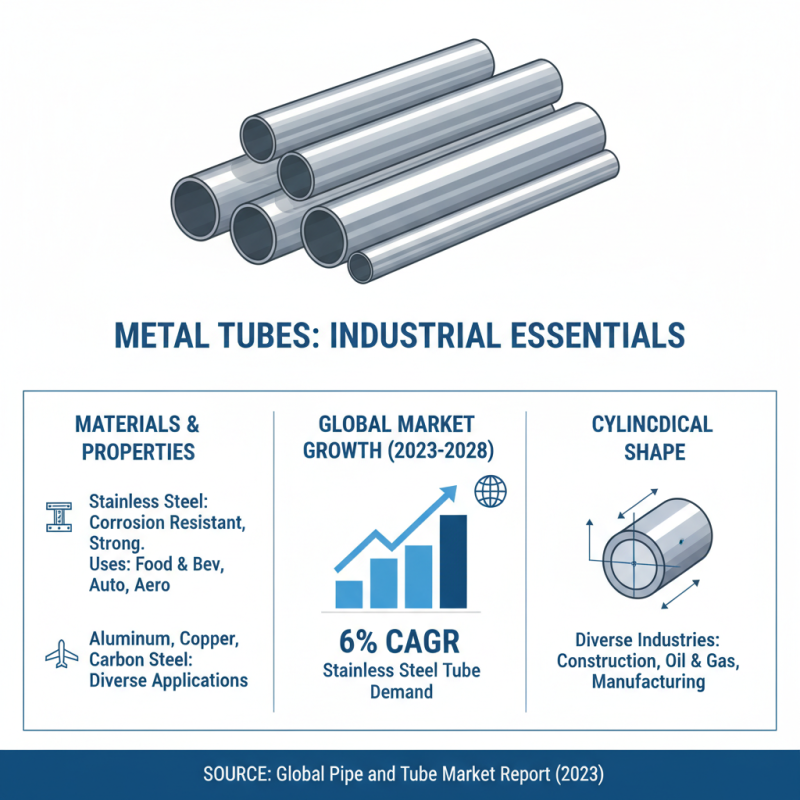

Metal tubes are essential components in various industries, characterized by their cylindrical shape and made from diverse metallic materials. These tubes can be manufactured from materials such as stainless steel, aluminum, copper, and carbon steel, each offering unique properties tailored to specific applications. For instance, stainless steel tubes are known for their corrosion resistance and strength, making them suitable for the food and beverage industry, where hygiene is crucial. According to a report by the Global Pipe and Tube Market, the demand for stainless steel tubes is projected to grow at a CAGR of 6% from 2023 to 2028, reflecting their increasing utility in sectors like automotive and aerospace.

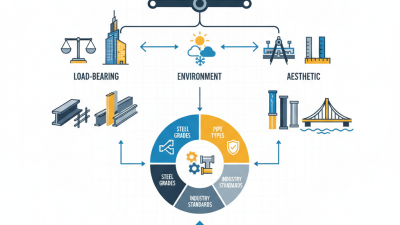

The composition of metal tubes typically involves alloying elements that enhance their physical and mechanical properties. For example, the addition of chromium in stainless steel not only improves corrosion resistance but also boosts hardness. Industry standards such as ASTM and ISO provide guidelines for manufacturing these tubes, ensuring they meet stringent safety and quality requirements. Data from the World Steel Association indicates that the global production of seamless and welded metal tubes reached over 30 million tons in 2022, driven by advancements in manufacturing technology and rising industrial output. The versatility and reliability of metal tubes make them indispensable in modern engineering, construction, and various technological applications.

Metal tubes are essential components across various industries, serving numerous applications due to their durability, versatility, and structural integrity. The industry primarily utilizes three types of metal tubes: seamless tubes, welded tubes, and ornamental tubes. Each type caters to specific needs and performance requirements.

Seamless tubes, typically manufactured through extrusion or rotary piercing, are favored in applications that demand high-pressure resistance and structural strength. According to a report by Grand View Research, the seamless tube market is projected to grow significantly, reaching a valuation of over $38 billion by 2025. In contrast, welded tubes, produced by rolling and welding flat plates, offer cost-effectiveness for various applications, including construction and automotive sectors. The global welded tube market is also on the rise, driven by increasing demand in infrastructure projects.

Ornamental tubes are utilized mainly in aesthetic applications, such as furniture and decorative architecture. These tubes are often designed with intricate patterns and finishes, catering to the growing trend for customized products among consumers. A market analysis by MarketWatch indicates that the demand for ornamental metal tubes is expected to increase, driven by a booming construction industry and rising consumer preference for stylish designs. These diverse types of metal tubes illustrate their indispensable role in modern industrial applications, supporting a wide range of critical functions.

The manufacturing processes for metal tubes encompass a variety of techniques that cater to diverse industrial requirements. One of the primary methods is seamless tube manufacturing, which involves extruding a solid billet of metal and then piercing it to create a hollow tube. This technique is particularly beneficial for applications requiring high strength and structural integrity, making it ideal for aerospace and automotive industries.

Another commonly used method is welded tube production. This process involves rolling flat metal sheets into a cylindrical shape and then welding the edges together. This technique allows for cost-effective mass production and can accommodate a range of sizes and thicknesses. Additionally, welded tubes can be produced in various shapes, including square and rectangular profiles, which are often used in construction, furniture, and packaging applications.

Further advancements in technology have introduced processes such as cold drawing and spiral welding, enhancing the versatility and performance of metal tubes. Cold drawing, for instance, involves reducing the diameter and increasing the length of a tube through a die, resulting in improved dimensional accuracy and surface finish. These manufacturing innovations have expanded the possibilities of metal tubes, making them essential components in modern industrial operations.

| Type of Metal Tube | Material | Common Applications | Manufacturing Process |

|---|---|---|---|

| Seamless Tube | Stainless Steel | Oil and Gas, Aerospace | Extrusion |

| Welded Tube | Carbon Steel | Structural Frameworks, Automotive | Welding and Forming |

| Square Tube | Aluminum | Furniture, Construction | Roll Forming |

| Rectangular Tube | Cold Rolled Steel | Manufacturing Equipment, Railing Systems | Cutting and Welding |

| Copper Tube | Copper | Plumbing, HVAC | Drawing |

Metal tubes play a crucial role across various industrial sectors due to their versatility, strength, and durability. In the automotive industry, for instance, metal tubes are widely used in exhaust systems, fuel lines, and structural components. According to a report by the International Organization of Motor Vehicle Manufacturers (OICA), the production of passenger cars alone reached approximately 77 million units in 2021, which underscores the significant demand for reliable materials like metal tubes to ensure vehicle integrity and performance.

In the construction sector, metal tubes are essential for frameworks, scaffolding, and plumbing systems. The Worldwide Construction Industry report indicates that the global construction market is projected to grow from $10 trillion in 2021 to over $14 trillion by 2025. This growth substantially increases the need for high-quality metal tubes, particularly in standard sizes like 1-inch and 2-inch diameters, ensuring safety and compliance with structural regulations. Additionally, the oil and gas industry leverages metal tubes in pipelines and drilling equipment, where the demand for corrosion-resistant materials is critical. A study from the American Petroleum Institute (API) reveals that the U.S. oil and gas extraction sector consumed over 1.5 million tons of metal tubing products in 2020, demonstrating their importance in facilitating safe and efficient operations.

Metal tubes have become integral components in various industrial applications due to their numerous advantages. One of the key benefits of using metal tubes is their exceptional strength and durability. Made from materials such as stainless steel, aluminum, and carbon steel, these tubes can withstand high pressures and temperatures, making them ideal for use in critical systems such as oil and gas pipelines, aerospace components, and automotive frameworks. Their resilience ensures reliability, minimizing the need for frequent replacements and maintenance.

Another significant advantage of metal tubes is their versatility. They can be manufactured in various sizes and shapes to meet specific requirements, which allows for their application in a wide range of industries—from construction to telecommunications. Metal tubes are also highly resistant to corrosion and environmental factors, ensuring long-lasting performance in harsh conditions. Additionally, their recyclability aligns with modern sustainability practices, making them an eco-friendly choice in today's industrial landscape. This combination of strength, versatility, and environmental responsibility underscores the critical role metal tubes play in advancing modern industrial applications.

"*" indicates required fields