"*" indicates required fields

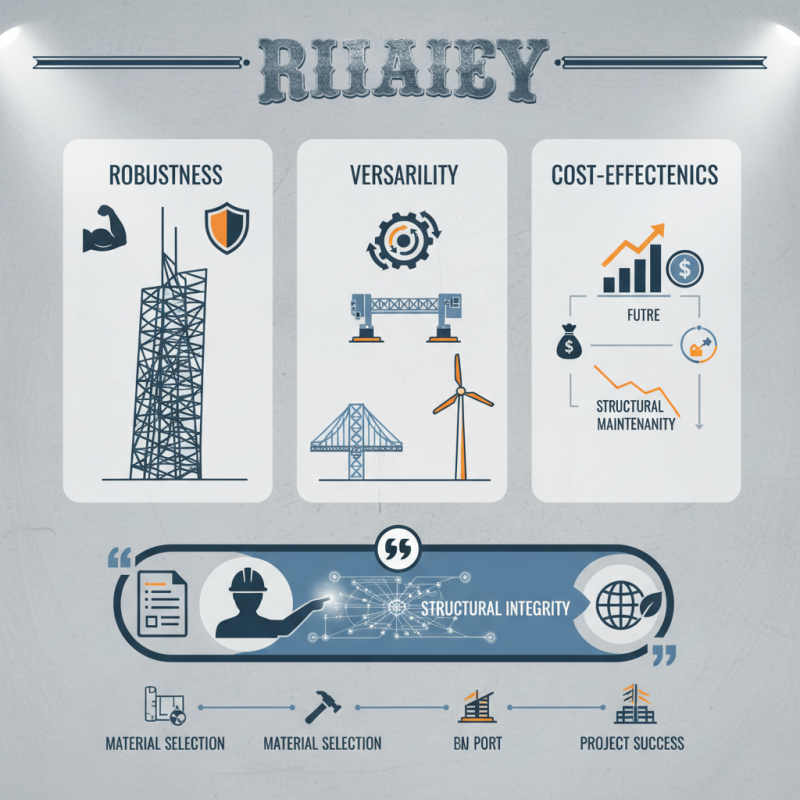

In the fast-evolving construction and manufacturing markets, choosing the right material is crucial for the success of any project. Among the various options available, western steel has emerged as a preferred choice due to its robustness, versatility, and cost-effectiveness. According to a recent report by the American Iron and Steel Institute, the use of high-quality steel in construction has led to a measurable increase in structural longevity, with proper material selection reducing maintenance costs by up to 30%.

Renowned industry expert Dr. John Smith, a leading researcher in the field of steel metallurgy, emphasizes the significance of this choice: "The quality of steel not only influences the structural integrity but also impacts the overall sustainability of a project." As projects increasingly demand durable materials that can withstand both time and environmental challenges, understanding the nuances of western steel becomes imperative for project managers and engineers alike. By applying expert insights and recognizing the essential characteristics of western steel, stakeholders can make informed decisions that ensure project success and sustainability.

When it comes to selecting the right Western steel for your projects, understanding the different types available is crucial. Western steel generally falls into two main categories: carbon steel and alloy steel. Carbon steel, known for its strength and durability, is often utilized in construction and manufacturing. It is available in various grades, each designed to meet specific mechanical properties. Alloy steel, on the other hand, contains additional elements such as chromium, molybdenum, or nickel to enhance its performance under varying conditions, making it suitable for more demanding applications.

When choosing the best type of Western steel for your project, consider the first tip: always assess the specific requirements of your application. Factors such as load-bearing capacity, environmental conditions, and welding compatibility play a significant role in determining which steel type will meet your needs effectively. Additionally, consult with industry experts or steel suppliers who can provide insights and recommend appropriate grades based on your project's demands.

Another essential consideration is the available certifications and standards that pertain to Western steel. Ensure that the steel you select meets relevant industry standards to guarantee quality and compliance. Finally, always weigh the cost against the long-term benefits of the steel type chosen. Sometimes investing in higher-grade steel may lead to significant savings in durability and maintenance over time, making it a smarter choice for your project.

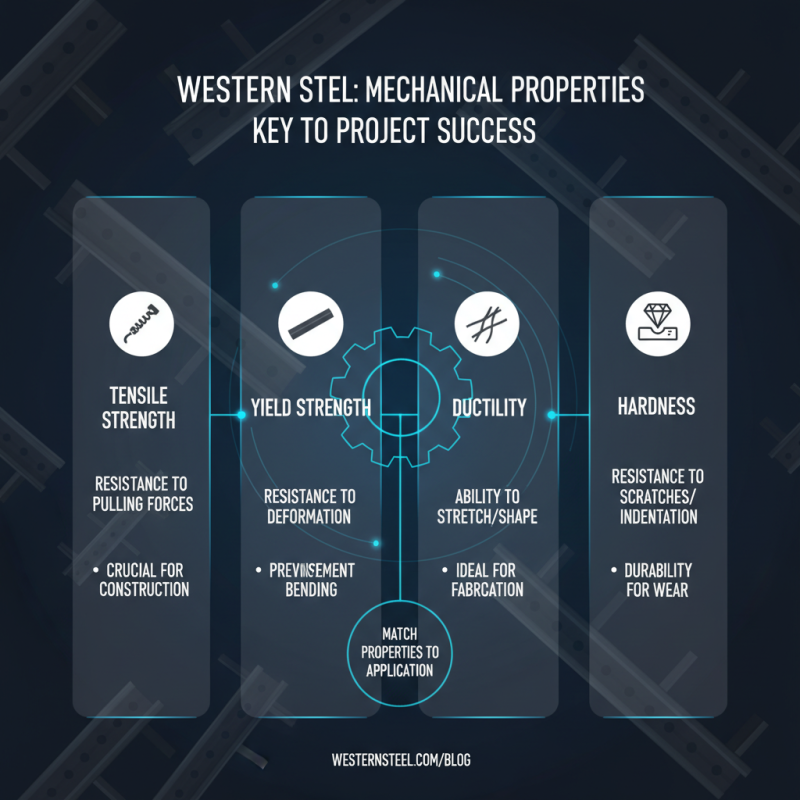

When selecting Western steel for your projects, understanding the mechanical properties is crucial to ensure that the material meets your specific requirements. Mechanical properties such as tensile strength, yield strength, ductility, and hardness play a significant role in determining how well the steel will perform under various conditions. It is essential to evaluate these properties based on the intended application of the steel, as different projects may demand different levels of performance. For instance, high tensile strength may be vital for construction applications, while excellent ductility could be more important for metal fabrication and shaping processes.

Additionally, factors such as weldability and corrosion resistance should not be overlooked. The compatibility between the steel's mechanical properties and the intended fabrication methods can significantly impact the overall integrity of the final product. Conducting thorough material testing and consulting technical data sheets can provide valuable insights into how the steel will react to stress, temperature changes, and environmental conditions. By prioritizing these mechanical properties, you can make a more informed decision and ensure that the western steel you choose will effectively support the success of your projects.

When selecting the best Western steel for your projects, assessing corrosion resistance and durability is paramount. Western steels are often exposed to varying environmental conditions, which can significantly impact their longevity and performance. Corrosion-resistant properties are essential for projects that may encounter moisture, chemicals, or salty air. Opting for steel grades treated with protective coatings or made from alloyed materials can enhance the longevity of your structures or products, ensuring they withstand the test of time.

Moreover, when evaluating durability, it’s crucial to consider the inherent properties of different steel types. Factors such as tensile strength, toughness, and impact resistance play a vital role in how well the steel will perform under stress. For applications in harsh environments, looking into steels designed to endure extreme conditions, including temperature fluctuations and heavy load-bearing, can make a significant difference.

Ultimately, by focusing on corrosion resistance and durability, you can select Western steel that not only meets the immediate needs of your project but also provides long-term reliability and effectiveness.

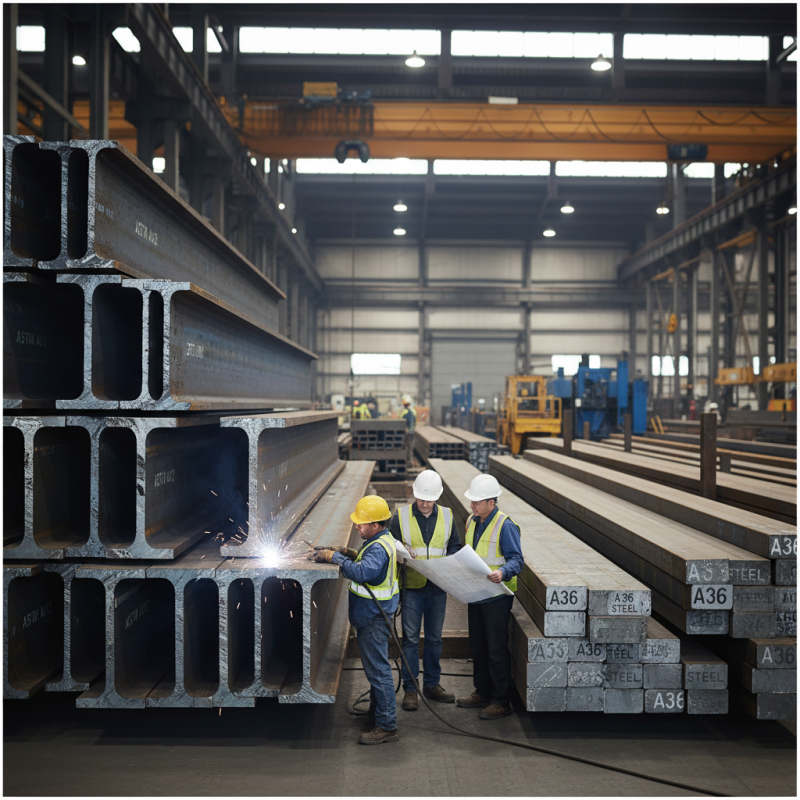

When selecting the appropriate grade of Western steel for specific applications, understanding the distinct properties of various steel grades is crucial. Western steel often includes a variety of alloy compositions, each tailored to meet specific engineering standards and project requirements. For instance, common grades like ASTM A992 are preferred for structural applications due to their excellent weldability and higher strength-to-weight ratios. Meanwhile, A36 steel is frequently chosen for general construction purposes due to its good mechanical properties and cost-effectiveness.

Moreover, the importance of corrosion resistance cannot be overstated, especially in applications exposed to harsh environments. Steel grades like A572 or weathering steels, such as ASTM A588, are recommended for projects where resistance to atmospheric corrosion is critical. According to the American Institute of Steel Construction (AISC), using the right grade of steel can enhance the longevity of structures and reduce maintenance costs by up to 30%. It’s essential for engineers and project managers to consider these details in order to optimize the performance and safety of their constructions while adhering to budget constraints and regulatory requirements.

When selecting Western steel for your projects, budgeting and cost considerations play a crucial role in the decision-making process. Understanding the full scope of expenses can help you make informed choices that align with your financial constraints. Start by assessing the overall budget available for your project, which should include not just the cost of the steel itself, but also factors such as transportation, fabrication, and installation. Being aware of the total expenditure upfront can prevent any financial surprises later on.

Moreover, consider the long-term implications of your steel selection. While cheaper options may seem appealing initially, they could lead to higher maintenance costs or a shorter lifespan, ultimately impacting the project’s total cost over time. Engaging with suppliers and seeking detailed quotes can also help clarify the expenses involved.

Look for value rather than just the lowest price; investing in quality materials can yield better results and greater satisfaction in the end. Balancing short-term savings with long-term investment is key to making the best choice when budgeting for your Western steel needs.

"*" indicates required fields