"*" indicates required fields

Choosing the right steel metal for your projects is a critical decision that can greatly impact the effectiveness and durability of your work. As noted by industry expert John Smith, a renowned metallurgist with over 20 years of experience, "The choice of steel metal is not merely a matter of preference; it determines the success and longevity of any structural endeavor." With a myriad of options available, from stainless steel to carbon steel, understanding the unique properties and applications of each type is essential for achieving the desired outcomes in your projects.

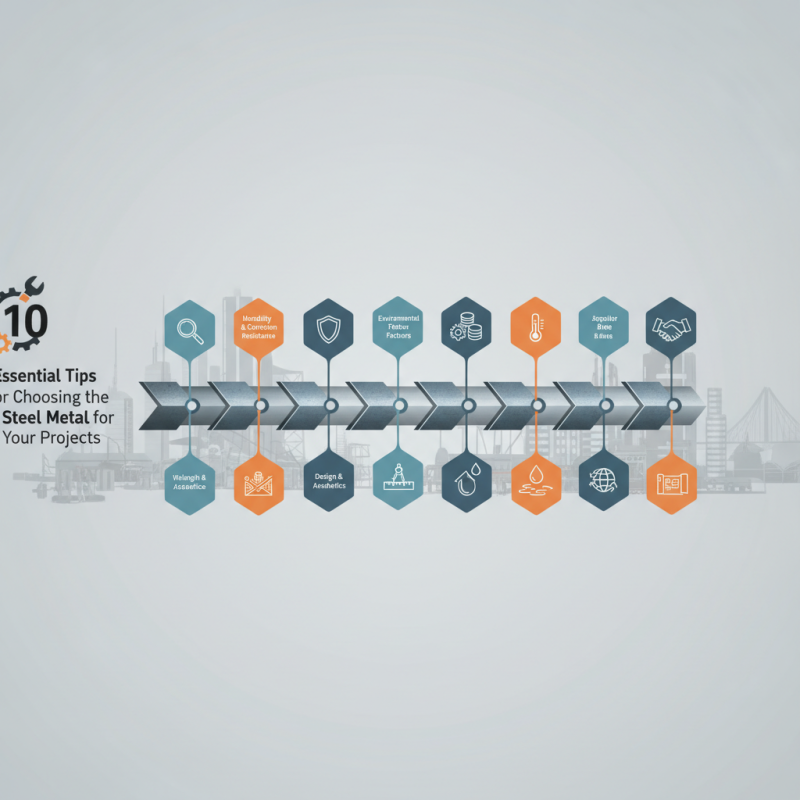

In an era where construction and manufacturing professionals are continually seeking to enhance the quality and efficiency of their work, relying on expertise to navigate the complexities of steel metal selection has never been more vital. This guide aims to distill the essential factors into 10 practical tips, empowering you to make informed choices that align with your specific project needs. Whether you're developing infrastructure, crafting intricate designs, or pursuing industrial applications, the right steel metal can serve as the backbone of your undertaking, ensuring not only structural integrity but also cost-effectiveness and aesthetic appeal.

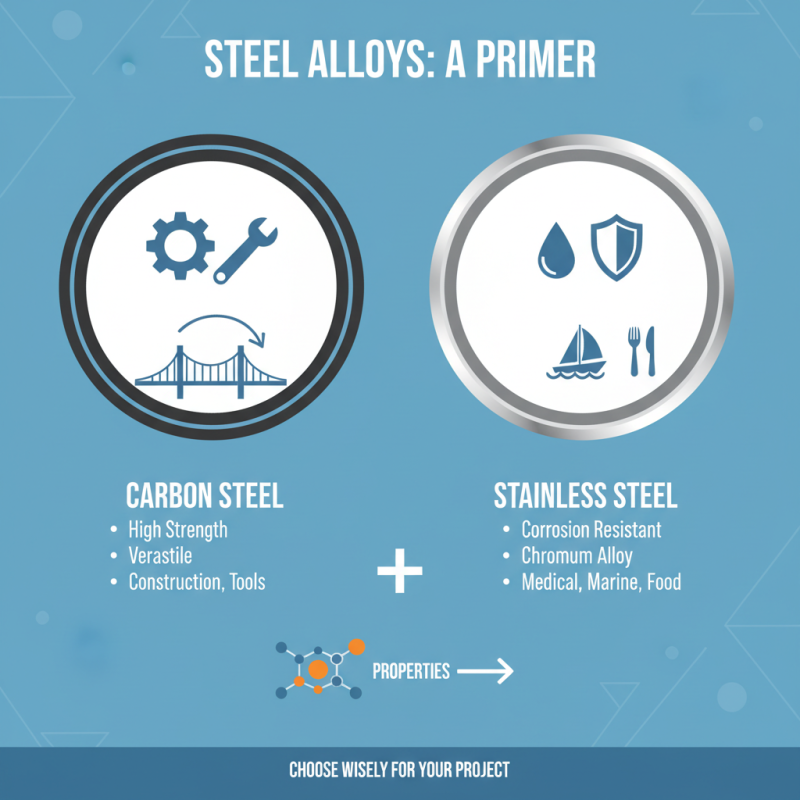

When embarking on a project that requires the selection of steel, understanding the various types of steel alloys and their properties becomes paramount. Steel is categorized based on its alloying elements, the most common being carbon and chromium. Carbon steel, for example, is known for its high strength and versatility, making it suitable for a wide range of applications. Meanwhile, stainless steel contains chromium, which provides excellent corrosion resistance, vital for projects exposed to harsh environments.

Beyond these primary categories, there are specialized alloys designed for specific characteristics. For instance, tool steel is formulated to withstand high impact and abrasion, making it ideal for manufacturing tools and dies. On the other hand, high-strength low-alloy (HSLA) steel offers better mechanical properties while maintaining low weight, commonly used in structural applications. By understanding these distinct properties and their implications on performance and longevity, you can make informed decisions that enhance the overall quality and success of your projects.

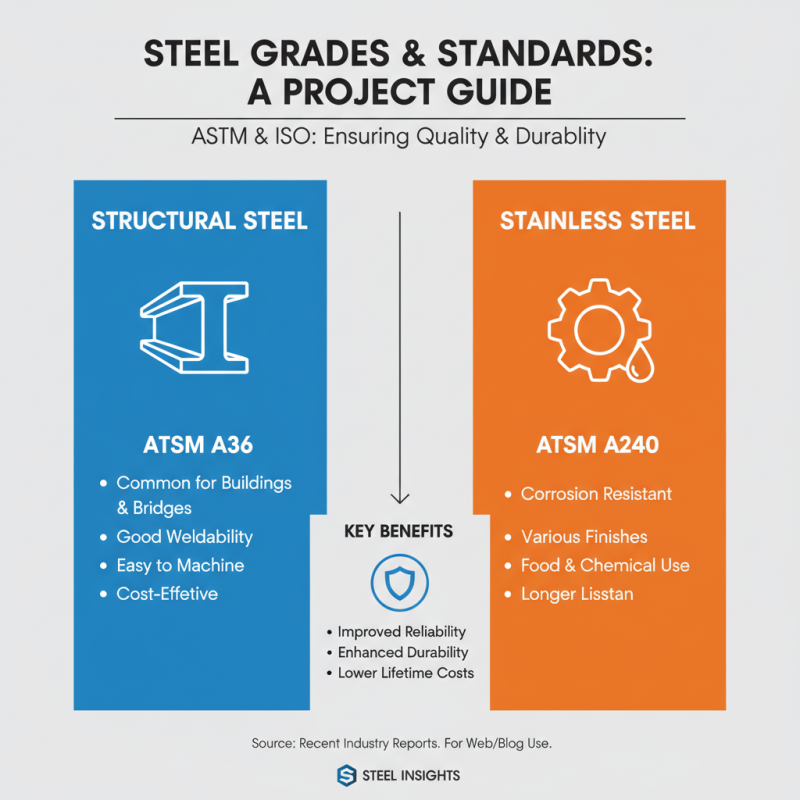

When selecting the appropriate steel for your projects, understanding the difference between various steel grades is crucial. ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) standards play a significant role in evaluating these grades. For instance, ASTM A36 steel is widely recognized for structural applications due to its good weldability and machinability. On the other hand, stainless steels may conform to standards like ASTM A240, which ensures that the material has excellent resistance to corrosion. According to recent industry reports, adherence to these standards can improve the reliability and durability of steel products, leading to lower lifetime costs for projects.

When choosing steel, always consider the intended use and environment. Tips for selecting the right steel include understanding the mechanical properties such as yield strength and tensile strength, which dictate how materials perform under stress. Additionally, evaluating the standard that the steel grade complies with will provide insights into its quality and performance criteria. It's essential to reference credible guidelines and data analysis reports; a study from the American Institute of Steel Construction indicates that correctly specified steel grades can achieve up to 30% higher efficiency in structural applications.

Furthermore, examining the impact of environmental conditions on the steel's performance is fundamental. For example, if the project is in a coastal area, opting for a grade that meets corrosion resistance standards, such as those outlined by ASTM or ISO, is advisable. Keeping an eye on recent industry trends can help in making informed decisions.

When selecting the appropriate steel for your project, understanding the corrosion resistance of different types of steel is crucial. Stainless steel, known for its exceptional resistance to rust and corrosion, is an alloy that contains a minimum of 10.5% chromium. This chromium forms a passive layer of chromium oxide on the surface, effectively protecting the steel from environmental factors. In environments where moisture and corrosive elements are prevalent, such as coastal areas or industries dealing with chemicals, stainless steel can be a superior choice, as it often lasts up to three times longer than carbon steel in these conditions.

On the other hand, carbon steel, although more economical and offering higher tensile strength, is significantly more susceptible to corrosion when exposed to moisture and oxygen. Reports from the National Association of Corrosion Engineers indicate that corrosion-related failures cost U.S. industries over $300 billion annually. Choosing carbon steel necessitates an understanding of protective measures, such as galvanizing or applying protective coatings, which can add to initial costs and ongoing maintenance requirements. Ultimately, assessing the specific environmental conditions and the longevity required for your project will guide you in deciding between stainless and carbon steel, ensuring you make an informed decision that balances performance and cost.

When embarking on a project that requires steel, cost often becomes a pivotal factor. Balancing budget constraints with the need for quality is essential to ensure project success. Higher-grade steel may come with a greater upfront cost, but investing in quality can lead to long-term savings through reduced maintenance, increased durability, and improved performance. Before making a decision, project managers should thoroughly evaluate the specific requirements of their projects, including the environment in which the steel will be used, load-bearing needs, and potential exposure to corrosion.

Another crucial aspect of cost analysis is understanding the trade-offs between various types of steel. For instance, while carbon steel might be more affordable, it may not provide the same level of strength or resilience as alloy or stainless steel in certain applications. Temporary fluctuations in steel prices due to market demand or supply chain issues can also affect budgeting. Therefore, securing quotes from multiple suppliers and considering bulk purchasing options can help mitigate these costs. By carefully assessing both the immediate and long-term financial implications of steel selection, project managers can make informed choices that align quality with budgetary constraints.

| Steel Type | Cost per Ton (USD) | Yield Strength (MPa) | Corrosion Resistance | Applications |

|---|---|---|---|---|

| Carbon Steel | $600 | 250 | Low | Structural Beams, Pipes |

| Alloy Steel | $800 | 350 | Medium | Gears, Shafts |

| Stainless Steel | $1500 | 200 | High | Food Industry, Medical Equipment |

| Tool Steel | $1200 | 400 | Low | Manufacturing Tools, Dies |

| High-Strength Low-Alloy Steel | $700 | 300 | Medium | Bridges, Heavy Equipment |

When selecting the appropriate steel metal for construction projects, understanding the load-bearing capacity and durability requirements is crucial. According to the American Institute of Steel Construction (AISC), the load-bearing capacity of a material is influenced significantly by its yield strength and modulus of elasticity. For example, structural steel with a yield strength of 36 ksi (kilo-pounds per square inch) can support substantial weights, making it ideal for beams and columns in heavy structures. Additionally, the moment capacity for these steel sections is critical in ensuring stability and safety over time.

Durability is another key factor to consider, as it affects the lifespan and maintenance needs of the structure. ASTM International has established various standards that define the corrosion resistance of different types of steel. For instance, weathering steel, which develops a protective patina, can last longer in harsh environments without the need for extensive coatings or treatments. A report by the National Association of Home Builders (NAHB) indicates that steel structures can have a service life exceeding 50 years, making them a valuable investment for long-term projects. Therefore, evaluating specific project requirements in terms of load-bearing and durability ensures the selection of the right steel type, ultimately enhancing the structural integrity and performance of the build.

"*" indicates required fields