"*" indicates required fields

When embarking on a construction or manufacturing project, one of the critical decisions you face is the choice of materials. Among various options, steel and aluminum stand out as two of the most commonly used metals, each with distinct characteristics that can significantly impact the outcome of your project. Understanding the differences between steel and aluminum is essential for making an informed decision tailored to your specific needs.

In this exploration, we will delve into the top 10 differences between steel and aluminum, highlighting aspects such as strength, weight, corrosion resistance, and cost. Steel, known for its durability and tensile strength, often excels in heavy-duty applications. In contrast, aluminum, with its lightweight and high malleability, is frequently favored in industries where weight savings are paramount. By examining the unique properties and advantages of steel and aluminum, you’ll be equipped to determine which material aligns best with your project requirements, ultimately guiding you toward a successful outcome.

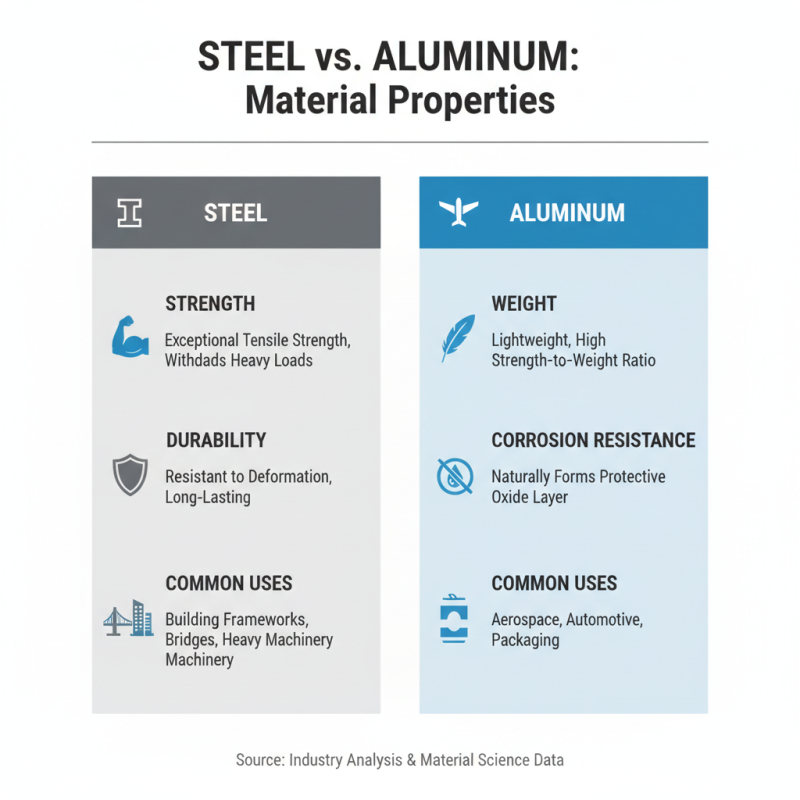

When comparing materials for construction and manufacturing, understanding the fundamental properties of steel and aluminum is crucial. Steel is known for its exceptional strength and durability, making it a preferred choice for structural applications. It has a high tensile strength and can withstand heavy loads, which is why it's commonly used in building frameworks and bridges. Additionally, steel's ability to resist deformation under pressure makes it ideal for applications requiring stability and longevity.

On the other hand, aluminum is prized for its lightweight nature and corrosion resistance. This makes it an excellent choice for applications where weight reduction is essential, such as in the automotive and aerospace industries. Despite being less strong than steel, advancements in aluminum alloys have significantly improved its strength-to-weight ratio, allowing it to be used in structural capacities as well. Furthermore, aluminum's capacity to resist rust makes it favorable for outdoor applications and environments where exposure to moisture is a concern. Each material has distinct advantages, and the choice between steel and aluminum ultimately depends on the specific requirements of the project at hand.

When comparing steel and aluminum, one of the most critical factors to consider is the strength-to-weight ratio. Aluminum is well-known for being lightweight, which makes it an attractive choice for applications where reducing weight is paramount. This attribute allows for easier handling and transportation, as well as lower fuel consumption in vehicles. On the other hand, steel, while heavier, is often stronger and can withstand greater loads, making it suitable for structures requiring high tensile strength.

When choosing between these two materials, it's essential to evaluate the specific requirements of your project. For applications requiring high strength in a lightweight format, aluminum might be the better option. However, if your project demands robust structural integrity and resistance to deformation under heavy loads, steel may be the more appropriate choice.

Tips: Consider the environment in which the project will be deployed. If the material will face harsh weather conditions, aluminum's corrosion resistance could be beneficial. Conversely, if cost is a primary concern, steel might offer more economical bulk pricing. Always weigh these factors relative to your project’s objectives to ensure the best performance and value.

When considering the cost implications of using steel versus aluminum for a project, it's crucial to analyze the initial investment and the long-term financial impacts of each material. Steel often comes at a lower upfront cost compared to aluminum, making it an attractive option for budget-conscious projects. This affordability can be particularly beneficial in large-scale applications where the material quantity required significantly affects overall budget. Additionally, the durability and strength of steel may lead to reduced maintenance costs over time, further enhancing its cost-effectiveness.

On the other hand, aluminum, while typically more expensive initially, offers advantages that can justify the higher price in specific contexts. It is lighter than steel, which can lower transportation and handling costs. Moreover, aluminum's resistance to corrosion can minimize the need for protective coatings and future repairs, ultimately saving money in maintenance. Understanding these cost dynamics is essential for selecting the right material to fit not only the project's budget but also its long-term financial forecast. Each material has its unique cost-benefit profile, and the decision should align with the specific needs and constraints of the project at hand.

| Property | Steel | Aluminum |

|---|---|---|

| Density | 7.85 g/cm³ | 2.70 g/cm³ |

| Strength | High tensile strength | Moderate tensile strength |

| Corrosion Resistance | Lower, requires protective coatings | High, naturally occurs through oxidization |

| Cost | Generally cheaper | Generally more expensive |

| Weight | Heavy | Lightweight |

| Workability | More difficult to fabricate | Easier to machine and weld |

| Thermal Conductivity | Moderate | High |

| Ductility | Moderate ductility | Higher ductility |

| Application | Used in construction, machinery | Used in aerospace, automotive |

| Recyclability | Highly recyclable | Highly recyclable |

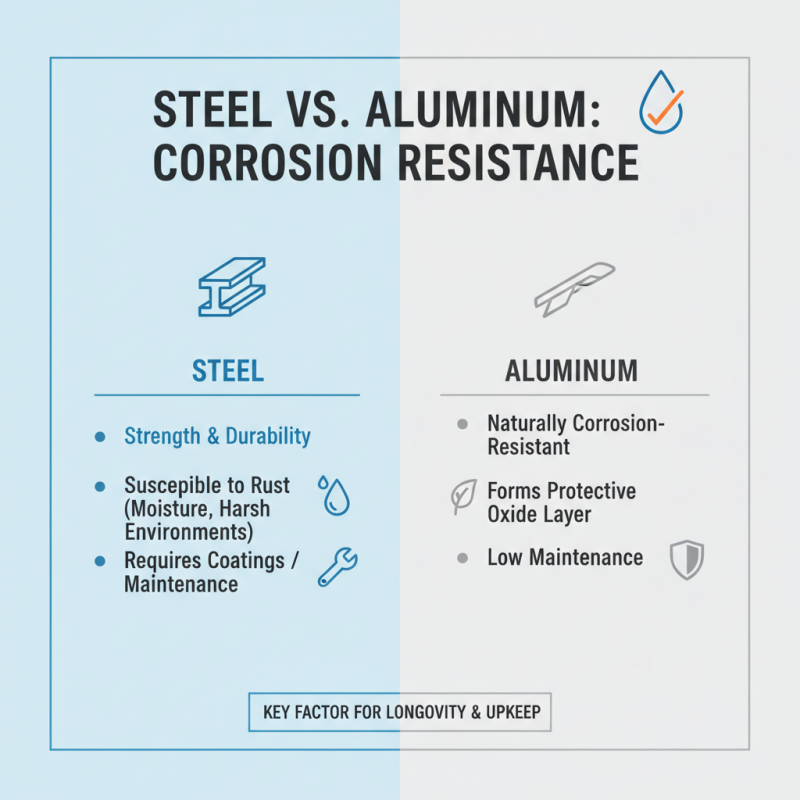

When considering materials for construction or manufacturing, corrosion resistance plays a crucial role in determining the lifespan and maintenance needs of steel and aluminum. Steel, while known for its strength and durability, is susceptible to rusting when exposed to moisture and harsh environments unless it is adequately treated or coated. This makes care and ongoing maintenance essential for steel structures to ensure their longevity, particularly in coastal or industrial settings where exposure to salt and chemicals is common.

On the other hand, aluminum boasts inherent corrosion resistance due to its ability to form a protective oxide layer when exposed to air. This layer helps inhibit further oxidation, allowing aluminum structures to resist corrosion even in harsh environments without the need for extensive coatings. As a result, aluminum generally requires less maintenance and can have a longer lifespan in corrosive atmospheres. These characteristics make aluminum an appealing choice for projects aimed at durability and reduced upkeep, particularly in applications like marine environments or outdoor installations.

When it comes to choosing between steel and aluminum for industrial applications, several key factors must be considered. Steel, known for its high tensile strength, is commonly used in construction and heavy machinery. According to the World Steel Association, over 1.8 billion metric tons of steel were produced globally in 2020, primarily for its durability and capability to withstand stress. Industries involving structural engineering, automotive manufacturing, and heavy-duty frameworks often prefer steel for these reasons. Its ability to be easily welded and formed also makes it a preferred material in manufacturing environments that require robust and lasting structures.

On the other hand, aluminum is favored in industries where weight reduction is critical, such as aerospace and automotive sectors. Aluminum's low density grants it an advantageous strength-to-weight ratio, making it ideal for applications where reducing weight can lead to enhanced fuel efficiency and performance. A report from the Aluminum Association indicates that using aluminum can reduce the weight of vehicles by up to 30%, translating to better fuel economy and lower emissions. Additionally, aluminum's resistance to corrosion further extends its applicability in environments prone to moisture and chemicals, ensuring longevity in diverse industrial applications. Understanding these differences enables project managers to make informed choices based on specific project requirements and environmental conditions.

"*" indicates required fields