"*" indicates required fields

Choosing the right materials for construction projects is a crucial step that can significantly impact the overall quality, durability, and efficiency of the structures being built. Among these materials, steel and pipe play a vital role due to their strength, versatility, and longevity. The decision regarding which type of steel and pipe to use can often be daunting, given the wide variety of options available on the market today. Understanding the specific requirements of your project, including load-bearing capacities, environmental exposure, and aesthetic considerations, is essential in making the right choices.

In this guide, we will explore the key factors to consider when selecting steel and pipe for your construction needs. We'll delve into the different grades and types of steel, the various applications of pipes in construction, and the importance of compliance with industry standards. By carefully evaluating these elements, you can ensure that your construction project rests on a solid foundation of quality materials, thus enhancing both safety and performance. With the right knowledge and approach, you can navigate the complexities of material selection and make informed decisions that will define the success of your construction endeavors.

When undertaking construction projects, understanding the different types of steel is crucial for ensuring structural integrity and longevity. The most common types of steel used in construction include carbon steel, stainless steel, and alloy steel, each serving distinct purposes. Carbon steel, known for its strength and affordability, is often used in beams and columns. On the other hand, stainless steel is favored for its corrosion resistance and aesthetic appeal, making it ideal for architectural applications and environments prone to moisture. Alloy steel offers enhanced properties and is used where specific strength and toughness characteristics are required.

Tips: When selecting steel for your project, consider the environmental conditions it will face. For example, if your construction site is in a coastal area, opting for stainless steel may be more beneficial due to its resistance to saltwater corrosion. Additionally, evaluate the load-bearing requirements of your structure to determine if carbon or alloy steel would be more suitable for your needs.

Furthermore, always consult with structural engineers to ensure that the chosen steel type meets safety standards and building codes. This step not only ensures compliance but also enhances the durability and performance of your construction project. By understanding these steel options and their applications, you can make informed decisions that contribute to the success of your build.

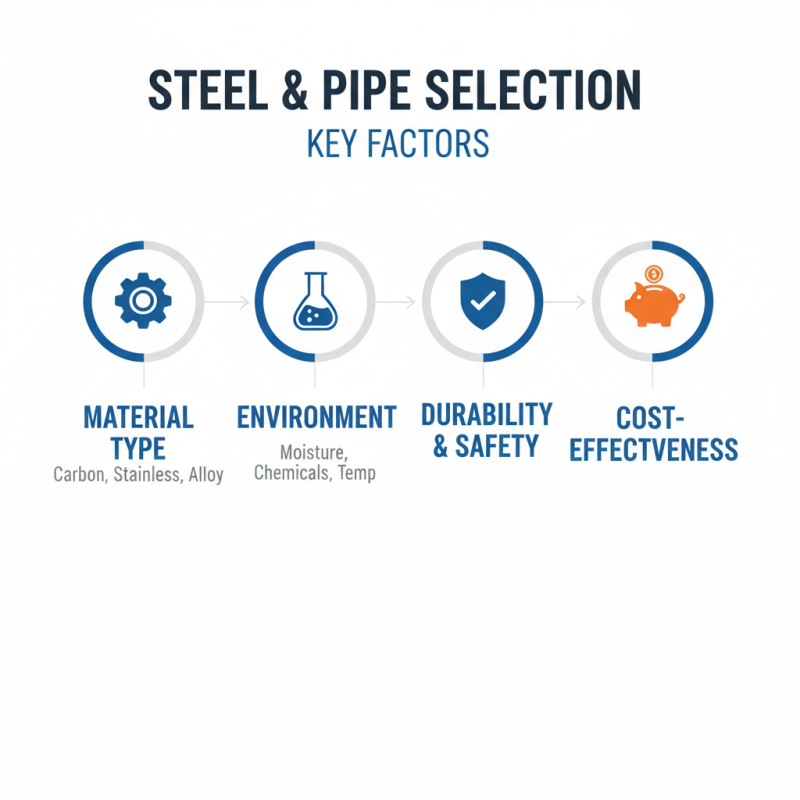

When selecting steel and pipe materials for construction projects, several key factors must be considered to ensure durability, safety, and cost-effectiveness. First and foremost, the type of material suitable for the specific application is crucial. Different grades and types of steel, such as carbon steel, stainless steel, or alloy steel, offer distinct properties such as strength, corrosion resistance, and weldability. Assessing the environmental conditions, such as exposure to moisture, chemicals, or extreme temperatures, will help determine the most appropriate material choice that aligns with project requirements.

In addition to material properties, the dimensions and specifications of the pipes must be evaluated. This includes factors like wall thickness, diameter, and pressure rating, which directly influence the performance of the piping system. Furthermore, understanding the project's structural requirements, load-bearing capacity, and applicable building codes is essential for compliance and safety. Engaging with suppliers and consulting engineering experts can provide valuable insights and help in making informed decisions that meet both functional needs and budgetary constraints.

When it comes to selecting the right steel and pipe for construction projects, cost-effectiveness plays a critical role. According to recent industry reports, the total cost of steel in a construction project can account for 15-30% of the overall budget. With varying steel types available, including carbon steel, stainless steel, and alloy steel, each has unique properties that can significantly affect performance and cost. For instance, carbon steel is often the most economical option, with prices typically ranging from $0.60 to $2.50 per pound, making it suitable for a wide variety of structural applications, while stainless steel, ranging from $2.00 to $5.00 per pound, offers enhanced corrosion resistance but at a higher cost.

Furthermore, the choice of pipe material is equally important in optimizing budget efficiency. In the construction sector, options include PVC, galvanized steel, and copper, each with distinct advantages and costs. Reports indicate that PVC can be the most cost-effective choice for drainage and plumbing applications, with prices around $0.50 to $1.50 per foot, while galvanized steel, which provides improved durability, typically ranges from $1.00 to $3.00 per foot. Understanding the long-term implications of these choices is vital; although initial costs may be lower with PVC, the longevity and maintenance requirements of steel pipes could justify their higher upfront price, ultimately impacting overall project expenses.

When embarking on a construction project, assessing the structural requirements is crucial to ensure safety and longevity. The type of steel and pipe used will significantly influence the stability of the structure, so understanding the load-bearing capacities and resistance to environmental factors is essential. Begin by evaluating the specific demands of your project, including the weight loads, environmental conditions, and any potential stresses that the materials will face.

**Tips:** Before selecting materials, consult with an engineer to analyze the structural demands accurately. This analysis will help determine which grades of steel or types of piping are best suited for your needs. Additionally, consider the method of fabrication and the potential for corrosion, which can impact the performance of the materials over time.

Furthermore, always review local building codes and regulations, as they dictate standards that must be met. This ensures compliance and enhances the safety and reliability of your construction. Engaging with professionals early in the process can save time and resources, leading to a more effective construction approach tailored to your project’s requirements.

**Tips:** Keep an eye on emerging technologies and innovations in material science. Utilizing the latest advancements can improve performance and durability, potentially reducing long-term costs. Staying informed about new materials might open up more options for achieving your project goals effectively.

| Material Type | Yield Strength (MPa) | Tensile Strength (MPa) | Typical Uses | Corrosion Resistance |

|---|---|---|---|---|

| Mild Steel | 250 | 400 | Construction Frames, General Fabrication | Low |

| High Strength Steel | 350 | 550 | Bridges, Heavy Load Structures | Medium |

| Stainless Steel | 210 | 520 | Piping, Food Processing Equipment | High |

| Galvanized Steel | 230 | 450 | Construction, Fencing | Medium to High |

The choice of steel and pipe materials in construction has significant implications for both sustainability and environmental impact. According to the World Steel Association, steel is one of the most recycled materials globally, with about 85% of the steel produced being recycled at the end of its life cycle. This high recycling rate not only reduces the demand for new raw materials but also minimizes energy use, resulting in lower greenhouse gas emissions. A study by the American Iron and Steel Institute indicates that using recycled steel can save up to 74% of the energy required compared to producing new steel from iron ore.

Moreover, the environmental impact of steel production varies based on the materials and methods used. For instance, opting for steel sourced from suppliers that adhere to sustainable forestry practices can significantly reduce deforestation and habitat destruction associated with mining activities. Additionally, modern production techniques, such as Electric Arc Furnace (EAF) technology, can further lower emissions and reduce water usage compared to traditional methods. According to the Global Steel Innovation Forum, implementing more sustainable practices in steel production could help to cut carbon dioxide emissions by over 50% by 2030. These considerations are essential for construction professionals aiming to make informed decisions that align with current sustainability goals.

"*" indicates required fields