"*" indicates required fields

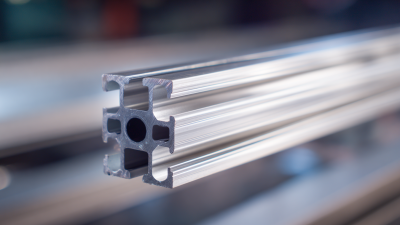

In recent years, the aluminum tube market has shown remarkable growth, driven by various industries. The global aluminum tube market size was valued at approximately $7 billion in 2022 and is projected to reach over $10 billion by 2026. This rise is largely due to the metal's lightweight properties and resistance to corrosion. Choosing the right aluminum tube can be a challenge, given the diverse applications and specifications available.

Different applications require specific aluminum tube characteristics. For instance, automotive and aerospace industries prioritize lightweight yet strong materials. The construction sector often looks for tubes that provide excellent insulation and fire resistance. A poorly chosen tube can lead to project delays and increased costs. Understanding the key metrics, such as wall thickness and alloy composition, is essential for project success.

Many professionals overlook details like surface finish and diameter. These factors can significantly impact performance and aesthetics. The aluminum tube must not only meet functional requirements but also align with project timelines and budgets. As the industry evolves, taking time to reflect on these aspects before making a decision is vital to ensure optimal results.

When selecting the right aluminum tube, understanding its types and applications is crucial. Different aluminum alloys serve varied purposes. For instance, the 6061 alloy is popular for structural applications due to its excellent mechanical properties. According to the Aluminum Association, about 65% of aluminum products made for construction use this alloy. It combines strength with good corrosion resistance, making it ideal for many projects.

On the other hand, the 6063 alloy is favored in architectural applications. It offers great extrudability, allowing for intricate shapes. This alloy is often used in window frames and architectural details. Interestingly, a report from the European Aluminium Association shows that about 30% of aluminum consumption in Europe is for building and construction. Knowing the right application type can save time and resources.

Choosing the right tube isn't just about the material. It also requires considering dimensions and wall thickness. A tube that is too thin may buckle under pressure while a thicker one could add unnecessary weight. The right fit ensures safety while also optimizing performance. Balancing these factors is essential and often overlooked.

Choosing the right aluminum tube for your project is critical. When assessing strength and weight requirements, you need to consider factors like load-bearing, stiffness, and flexibility. According to the Aluminum Association, aluminum has a strength-to-weight ratio that is superior to many other materials. It’s pivotal for projects where lightweight structures are essential.

Weight reduction can enhance efficiency. For instance, aerospace applications typically use aluminum tubes because they are lightweight and strong. Data from the Federal Aviation Administration indicates that reducing weight by just 1% in aircraft can save 3,000 gallons of fuel over a year. Yet, you may face challenges. Not all aluminum alloys offer the same strength. Some may bend or warp under stress, failing to meet your project's needs.

Evaluating stress limits is a key step. Look at structural requirements carefully. An under-engineered tube risks not just failure but also safety. Some projects need an aluminum tube that can withstand internal pressure or external forces. It’s important to match strength ratings with expected loads. The wrong choice can lead to costly mistakes or dangerous outcomes. Remember, a balance between strength, weight, and cost is crucial. Decision-making should not overlook the implications of material selection.

Choosing the right aluminum tube can be a crucial decision for your project. Cost and quality often clash in this selection process. According to industry reports, 70% of project managers emphasize the importance of balancing these two aspects. Higher-quality aluminum tubes may come at a steeper price, but they typically offer better strength and longevity. In contrast, cheaper options may lead to issues down the line, affecting overall project success.

When evaluating cost versus quality, remember that a lower initial cost might hide future expenses. Maintenance and replacements can quickly add up. Experts recommend considering total lifecycle cost. This approach provides a clearer picture of what you might spend over time.

Choosing the right finish and coating for aluminum tubes is crucial for enhancing durability. Aluminum is lightweight and resistant to corrosion, but its performance can significantly vary based on surface treatment. A well-chosen finish not only increases lifespan but also improves aesthetics.

For projects exposed to harsh conditions, consider anodizing. This process creates a thick oxide layer that enhances corrosion resistance. According to a 2022 industry report, anodized aluminum can last up to five times longer than untreated alternatives. Powder coating is another option, offering a range of colors and excellent UV protection. It can withstand extreme temperatures and is ideal for outdoor applications.

Tips: Always evaluate your project environment. If you expect significant wear, select a tougher finish. Keep in mind that not all coatings adhere well to every type of aluminum. Test samples before committing. Remember, imperfections in application can lead to premature failure. Aim for consistency, but some variations may occur, and that’s part of the process.

In summary, the finish you choose plays a critical role in your project's overall success. While aesthetics matter, performance should be prioritized. A balanced approach will serve you best in the long run.

Choosing the right aluminum tube involves careful consideration of various specifications. First, the diameter and wall thickness are crucial. A thicker wall increases strength but adds weight. This can be a downside if your project requires lightweight materials.

Next, the alloy type affects performance. Some alloys are more corrosion-resistant, while others offer better machinability. Think about what your project demands. Will it face harsh environments? Or does it need precise machining? Reflect on these questions carefully.

Length is another non-negotiable factor. Custom lengths can be a challenge but are often necessary for specific applications. Ensure that the length meets your project's needs. Don't overlook the finishing options too. Anodizing provides a protective layer but may impact the tube's tolerances. Be wary of how each choice influences your design. Balancing all these elements can be complex, and your choice may not be perfect. It's essential to iterate on your specifications.

"*" indicates required fields