"*" indicates required fields

In the realm of construction and manufacturing, the selection of materials plays a crucial role in determining the success of any project. Among various materials, aluminum struts have gained significant popularity due to their unique combination of strength, lightweight, and corrosion resistance. According to a recent industry report by Research and Markets, the global aluminum market is projected to reach $189.75 billion by 2025, with significant growth in the usage of aluminum components like struts across several sectors including aerospace, automotive, and construction.

Choosing the right aluminum strut for your next project requires a thorough understanding of your specific needs and how various factors intersect with the properties of aluminum. The increasing demands for lightweight and durable construction materials have led to advancements in aluminum alloys, enhancing their performance in various applications. Moreover, a report from Grand View Research highlights that aluminum's recyclability and sustainability contribute to its appeal, positioning aluminum struts as a vital component for environmentally-conscious projects.

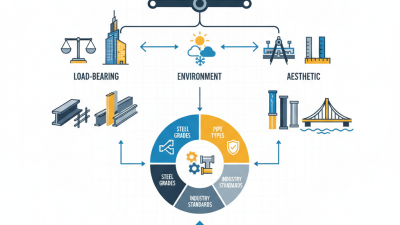

As we explore the decision-making process involved in selecting aluminum struts, it is critical to evaluate factors such as load-bearing capacity, size, and application environment. Making informed choices can significantly impact project durability and success, demonstrating the importance of understanding the advantages and specifications of aluminum struts in the ever-evolving landscape of material science.

When selecting the appropriate aluminum strut for your project, understanding the specifications is crucial. Key factors to consider include the load capacity, length, and wall thickness of the strut. The load capacity determines how much weight the strut can support, which is vital for ensuring safety and structural integrity. Make sure to calculate the total load your project will require and match it with the strut's specifications for optimal performance.

Another important aspect is the length and wall thickness of the aluminum strut. Longer struts may be necessary for larger projects, but they can also introduce challenges in terms of stability and weight distribution. The wall thickness affects the overall strength of the strut; thicker walls typically provide greater durability but can also increase the weight, affecting the ease of installation.

Tips: Always review the environmental factors your strut will face, such as humidity and temperature changes, as they can influence material performance over time. Additionally, consider consulting with a structural engineer to validate your choices and ensure your project meets safety standards. By combining these insights, you can make informed decisions that enhance the efficiency and effectiveness of your project.

When choosing the right aluminum strut for your next project, considering the materials' strength and weight is crucial. Aluminum struts are commonly used in various applications, including construction, automotive, and manufacturing, due to their favorable strength-to-weight ratio. According to a report by the Aluminum Association, aluminum is about one-third the weight of steel yet can match or exceed steel's strength in certain conditions. This characteristic makes aluminum struts particularly advantageous in projects where reducing overall weight is essential, such as in aerospace and transport structures.

Moreover, the tensile strength of different aluminum alloys varies significantly, influencing the strut's performance in various environments. For instance, 6061 aluminum alloy is known for its excellent corrosion resistance and is often used in marine applications, while 7075 aluminum, which has higher strength properties, is favored in applications requiring heavy-duty performance. A study by the Institute of Materials indicates that choosing the right alloy can lead to a weight reduction of up to 40% without compromising structural integrity, a critical factor in optimizing project efficiency and durability. Selecting the appropriate aluminum alloy tailored to the specific needs of your project can greatly enhance the performance and longevity of your structural components.

When selecting the right aluminum strut for your next project, accurate sizing is paramount. The performance of aluminum struts is largely determined by their dimensions and the load they will bear. Key measurements to consider include the length, width, and wall thickness of the strut, as even slight differences can significantly affect structural integrity. According to the Aluminum Association, the mechanical properties of aluminum, including tensile strength and yield strength, are vital for determining whether a specific strut can withstand the intended loads without deforming.

Essential calculations also play a critical role in sizing aluminum struts. Engineers frequently use the Euler's buckling formula to estimate the critical load for long struts, which helps in determining the optimal length and dimensions needed for safety under axial loads. According to data from the American Institute of Steel Construction, adjusting wall thickness can enhance the strut's ability to resist buckling, making it critical to choose dimensions that not only meet the physical space requirements but also the engineering demands of the project. As a rule of thumb, it is advisable to overestimate the load-bearing capacity to provide an adequate safety margin, keeping in line with industry recommendations.

When selecting the right aluminum strut for your next project, it's essential to consider the specific applications and requirements unique to your needs. Aluminum struts serve a variety of purposes, from structural support in construction to framework in automotive applications. The first step in application-based selection is to evaluate the load-bearing requirements of your project. Struts come in different sizes and thicknesses, so ensuring that the selected material can handle the expected weight and stress is crucial for maintaining structural integrity.

In addition to load capacity, the environment where the strut will be used plays a significant role in the selection process. For projects in corrosive settings, such as marine environments, opting for treated or anodized aluminum can enhance durability and longevity. Furthermore, you should consider factors like ease of installation and maintenance, as some designs may offer greater flexibility or adaptability to unique project specifications. By carefully assessing these application-based factors, you can ensure that your chosen aluminum strut meets both your functional and aesthetic needs, ultimately contributing to the success of your project.

When selecting the right aluminum strut for your next project, understanding industry standards and certifications is essential for ensuring quality and reliability. Aluminum struts are utilized in a variety of applications, from construction to automotive engineering, making adherence to recognized standards critical. Key certifications, such as those from ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization), provide guidelines on material properties, structural integrity, and safety. By choosing struts that meet these stringent criteria, you can gain confidence in the performance and longevity of your project.

Moreover, familiarity with the relevant industry standards can guide you in evaluating the specifications of aluminum struts. For example, knowing the significance of yield strength, tensile strength, and corrosion resistance will help you choose materials that align with your project requirements. Additionally, certifications often indicate that manufacturers employ rigorous quality control measures throughout the production process. This not only ensures that the struts you choose will withstand the demands of their intended use but also protects your investment by minimizing the risk of unexpected failures or maintenance issues down the line.

| Dimension (mm) | Weight (kg) | Load Capacity (kg) | Material Grade | Certification |

|---|---|---|---|---|

| 50 x 50 x 3 | 5.6 | 200 | 6061-T6 | ISO 9001 |

| 80 x 40 x 4 | 7.4 | 300 | 6063-T5 | ASTM B221 |

| 100 x 50 x 5 | 9.2 | 500 | 6082-T6 | EN 755-2 |

| 90 x 90 x 4 | 8.0 | 400 | 6005-T5 | ISO 14001 |

| 120 x 60 x 6 | 11.3 | 600 | 7075-T6 | MIL-ASTM |

"*" indicates required fields