"*" indicates required fields

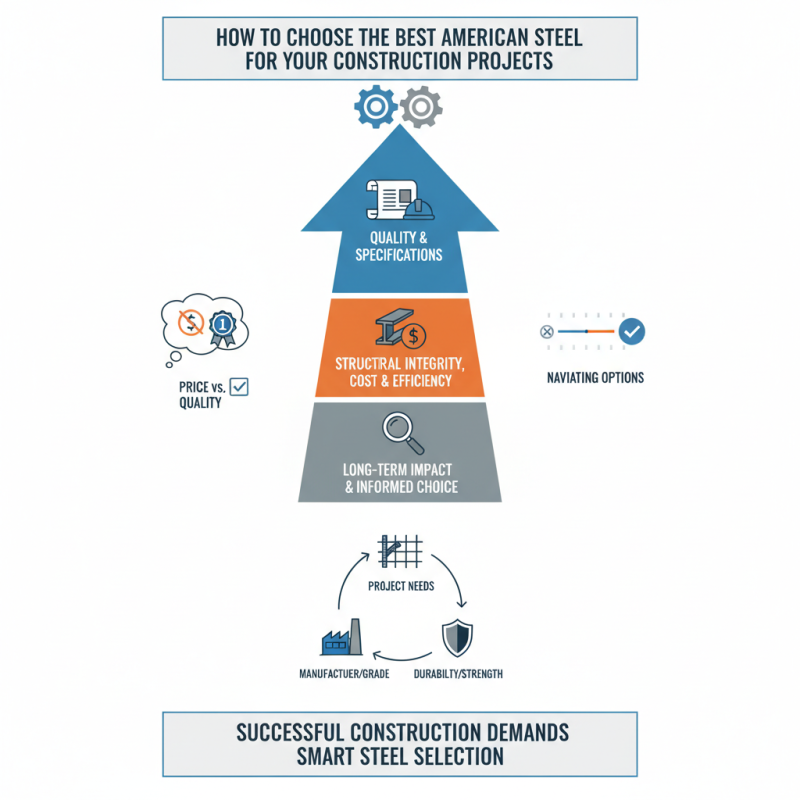

Choosing the best American steel for construction projects requires careful consideration. According to John Smith, a leading expert in the American steel industry, “Quality and specifications dictate the success of any project.” This insight is crucial for contractors and builders alike.

American steel is renowned for its durability and strength. However, the variety in grades and types can be overwhelming. Each project may demand a specific type of steel. Choosing the right one affects not only structural integrity but also cost and efficiency. Often, builders overlook these factors. They might choose based on price rather than quality.

Navigating through numerous options can be challenging. Many forget to consider the long-term impact of their choices. Reflecting on the material's properties is important. Even minor misjudgments can lead to significant setbacks later. Therefore, making an informed choice about American steel is vital for successful construction.

When selecting American steel for construction, understanding the types available is crucial. Varieties like carbon steel, alloy steel, and stainless steel serve different purposes. Carbon steel, for instance, is widely used for structural components due to its strength and affordability. In fact, reports indicate that approximately 70% of steel used in construction falls into this category.

Alloy steel adds different elements to enhance performance. This type is often used in projects requiring high strength and resistance to wear. Research shows that alloy steel can increase structural durability by up to 30%, making it a preferred choice for demanding applications. Yet, its cost can be a barrier, requiring careful budgeting.

Stainless steel is another important type. It offers excellent corrosion resistance and aesthetic appeal. However, it can be significantly more expensive than carbon options. Some construction managers might overlook the initial cost for long-term savings. This decision often requires reevaluation of project needs and specifications, considering both immediate budget constraints and future maintenance.

When selecting steel for construction, several key factors come into play. The type of steel is crucial. Mild steel, for instance, is popular for its versatility. Stainless steel, however, resists corrosion, ideal for structures exposed to harsh environments. Always evaluate the project requirements before making a choice.

One important aspect is the steel's yield strength. Higher yield strength means better performance under stress. Consider the load the structure will bear. For larger buildings, you need stronger materials. Make sure to consult with an engineer for the best advice on specifications.

Tips: Always review the material testing reports. Don’t rely solely on supplier claims. Additionally, think about the steel’s lifespan. Some may require maintenance sooner than others. Reflect on your budget, but remember that cheaper isn’t always better. High-quality steel often proves more cost-effective in the long run.

When selecting steel for construction, strength and durability are paramount. Steel's strength is often tested through its tensile strength. It refers to how much pull the steel can withstand before breaking. Look for materials that boast high tensile strength. A high number indicates the steel will perform well under pressure.

Durability is equally essential. Steel can rust over time if not properly treated. Examine the protective coatings available. These can significantly extend the lifespan of the material. You might find that some coatings significantly improve resistance to elements. However, not all steel comes with adequate protection. Reflect on the environment where the steel will be used; moisture, temperature, and pollutants can affect longevity.

Consider the impact of weight. Lightweight steel can be easier to handle but may not be as strong. Balancing weight and strength is crucial. Sometimes, the cheaper option might bring unforeseen costs later. Always think long-term. Investing in the right materials now can prevent failures in the future.

When selecting American steel for your construction projects, understanding cost and availability is crucial. Prices can vary significantly based on steel type and supplier. It’s important to compare quotes from different sources. Don’t forget to factor in transportation costs, as they can add up quickly. Some regions might have better access to certain types of steel, impacting availability.

Tips: Always check for local suppliers first. They often have lower shipping fees. Consider seasonal demand peaks, as prices fluctuate during busy construction periods. Steel shortages can occur, leading to higher costs. Planning ahead can mitigate these issues.

Assessing your requirements is vital. Are you using steel for structural support or aesthetic purposes? Different projects may need varying grades. Think about the long-term value of the material. Sometimes, the cheapest option isn't the most reliable. A focus on durability could save money over time, but it requires upfront investment. Reflect on your project’s needs and budget constraints.

| Steel Type | Cost per Ton | Availability (Lead Time) | Major Uses |

|---|---|---|---|

| Carbon Steel | $700 | 2-4 weeks | Beams, Columns, Rebar |

| Alloy Steel | $900 | 4-6 weeks | Heavy Machinery, Tools |

| Stainless Steel | $1200 | 3-5 weeks | Piping, Architectural Structures |

| Structural Steel | $850 | 3-4 weeks | Building Frameworks, Bridges |

| Reinforcing Steel | $600 | 2-3 weeks | Concrete Reinforcement |

Choosing steel for construction involves more than just strength. It’s essential to consider sustainability and environmental impact. Steel production can be energy-intensive. Emissions contribute to climate change. Using recycled steel reduces these impacts significantly. It also conserves natural resources.

When sourcing steel, look for suppliers that prioritize eco-friendly practices. Some methods use less water and reduce carbon footprints. However, not all steel is created equal. Sometimes, the cheaper options might not be the best choice environmentally. It's vital to weigh cost against ecological impact.

Think about the lifecycle of steel products. Where do they come from? How long will they last? Short-lived materials lead to more waste. Investing in durable, sustainable steel could be more beneficial long-term. Reflecting on these choices can lead to better outcomes for the environment and your project.

"*" indicates required fields