"*" indicates required fields

When it comes to selecting the best aluminum tube for your project needs, the process can often be daunting due to the vast array of options available. As industry expert James Anderson, who has over two decades of experience in metal fabrication, states, “Choosing the right aluminum tube is crucial not only for structural integrity but also for cost-effectiveness in any project.” His insights underscore the importance of understanding the specific requirements of each application to ensure optimal performance and durability.

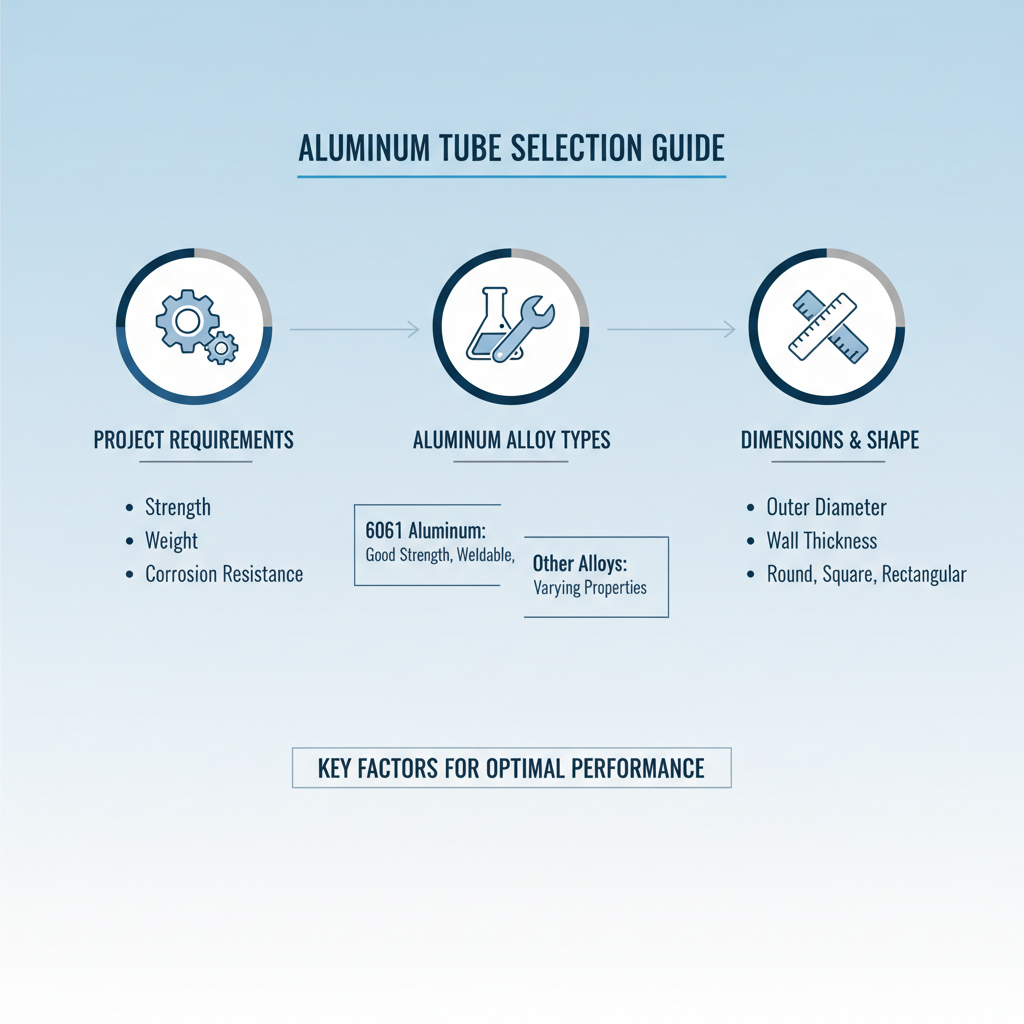

Aluminum tubes are widely used in various industries—from aerospace to construction—thanks to their lightweight nature and resistance to corrosion. However, the key to success lies in understanding the specific characteristics of different aluminum alloys, dimensions, and manufacturing processes. Whether you are embarking on a new construction project or designing a sophisticated piece of machinery, the decision-making process requires careful consideration of factors such as strength, weight, and environmental conditions. By honing in on these elements, one can make an informed choice that ensures the aluminum tube selected aligns perfectly with the intended use and project goals.

When selecting the best aluminum tube for your project in 2025, it's crucial to understand the various types available on the market. Aluminum tubes are categorized primarily by their structural properties and applications. According to the Aluminum Association, structural aluminum tubes are often classified as 6061 and 6063 alloys, each offering distinct advantages based on strength, corrosion resistance, and weldability. For example, the 6061 alloy is known for its high strength-to-weight ratio, making it ideal for heavy-duty applications, while 6063 is preferred for architectural purposes due to its excellent finishing capabilities.

**Tip:** Always assess the intended use of the aluminum tube. For projects requiring high tensile strength, opt for 6061 alloy tubes. If aesthetics and surface finish are more critical, consider 6063 alloy tubes.

Additionally, you'll find that aluminum tubes come in different shapes, including round, square, and rectangular sections. Each shape serves unique purposes; round tubes are often used for structural applications and fluid transport, while square and rectangular tubes are popular in manufacturing and construction due to their ease of fabrication. Industry reports indicate that the demand for square aluminum tubing is expected to grow by 4% annually through 2025, driven by increased construction activity.

**Tip:** Research specific standards and sizes for aluminum tubes before purchasing to ensure compatibility with your project's requirements. Always verify compliance with relevant industry standards to maintain quality assurance.

| Type of Aluminum Tube | Alloy Series | Typical Application | Strength (MPa) | Corrosion Resistance |

|---|---|---|---|---|

| Seamless Aluminum Tube | 6000 Series | Automotive Components | 205 | Moderate |

| Welded Aluminum Tube | 3000 Series | Construction | 210 | High |

| Square Aluminum Tube | 6005 Series | Furniture and Fixtures | 220 | Moderate |

| Round Aluminum Tube | 7000 Series | Aerospace | 250 | High |

| Anodized Aluminum Tube | 5005 Series | Electronics Housing | 180 | Very High |

When choosing the best aluminum tube for your project needs, it’s essential to consider several key factors that can significantly impact performance and functionality. First, evaluate the specific requirements of your project, including the desired strength, weight, and corrosion resistance. Different aluminum alloys offer various properties; for instance, 6061 aluminum is often favored for its good mechanical properties and weldability, making it suitable for a wide range of applications.

Additionally, consider the tube dimensions, such as diameter and wall thickness, which will influence the tube's overall structural integrity and how it fits into your project design. Manufacturing methods also play a crucial role; extruded aluminum tubes tend to have consistent strength and uniformity, while welded tubes might be more appropriate for custom shapes. Lastly, keep an eye on market trends, including cost fluctuations due to external factors like tariffs on aluminum imports, as these can affect your project's budget and material availability.

When selecting aluminum tubes for your project, evaluating their strength and durability is crucial. Aluminum is renowned for its lightweight yet robust nature, making it an ideal choice for various applications. The strength of an aluminum tube is influenced by factors such as its alloy composition, wall thickness, and manufacturing process. Alloys like 6061 and 7075 offer superior strength-to-weight ratios, with 7075 being particularly favored in aerospace applications due to its high tensile strength.

Durability goes beyond mere strength; it also encompasses resistance to environmental factors such as corrosion and fatigue. Anodized aluminum tubes can provide enhanced protection against corrosion, extending the life of your project components. When assessing durability, it's essential to consider the intended use of the aluminum tube. For outdoor applications, tubes with higher corrosion resistance are necessary, while those used in high-load situations should prioritize structural integrity. By understanding these factors, you can make an informed choice that aligns with your project's specific requirements.

When selecting the best aluminum tube for your project needs, understanding the cost-effectiveness of various options is crucial. According to a report by the Aluminum Association, the price of aluminum materials has seen a steady increase, averaging around $1,800 per ton in recent years. However, the overall lifecycle cost must also include considerations such as durability, weight, and corrosion resistance, which significantly impact long-term value. For instance, while a standard extruded aluminum tube might be cheaper upfront, the higher maintenance costs related to corrosion could negate initial savings.

Additionally, a study published in the Journal of Materials Engineering highlighted that tubes made from high-strength aluminum alloys can have a higher initial cost but result in a reduced weight, leading to lower transportation and installation expenses. In certain applications, using advanced aluminum tubes can provide a total cost savings of up to 30% when factoring in reduced operational costs and improved efficiency over time. As a result, investing in the right type of aluminum tube, tailored to specific applications, can lead to notable savings that extend far beyond the purchase price.

In 2025, the applications of aluminum tubes span a diverse range of industries, showcasing their versatility and efficiency. One of the primary sectors benefiting from aluminum tubes is the aerospace industry, where lightweight materials are crucial for improving fuel efficiency. According to a report by the International Lightweight Materials Association, the use of aluminum in aircraft manufacturing has increased by 12% over the past five years, underpinning a growing trend toward more sustainable aviation practices.

The automotive industry is also experiencing a significant shift with the adoption of aluminum tubes. A study by the Automotive Aluminum Alliance indicates that aluminum content in vehicles is projected to exceed 200 billion pounds annually by 2025, driven by the need for lighter components to enhance electric vehicle performance. Coupled with their corrosion resistance and recyclability, aluminum tubes have become essential in automotive design, offering manufacturers not only weight reduction but also enhanced safety features through increased structural integrity.

Furthermore, the construction sector utilizes aluminum tubes for their exceptional strength-to-weight ratio, which enables more agile and efficient building practices. The Aluminum Association forecasts that the use of aluminum in construction will grow by 15% through 2025, largely due to increased demand for energy-efficient buildings and sustainable construction materials. This trend illustrates the industry's recognition of aluminum not just as a replacement for heavier materials, but as a crucial component for future-oriented projects across various fields.

"*" indicates required fields