"*" indicates required fields

Selecting the right materials is crucial for the success of any construction project, and in 2025, the importance of choosing the right steel and pipe cannot be overstated. With advancements in technology and evolving industry standards, it is essential for builders and contractors to understand the diverse range of steel and pipe options available in the market. This knowledge not only contributes to the durability and longevity of structures but also impacts safety, efficiency, and cost-effectiveness during the construction process.

As the construction landscape continues to change, factors such as sustainability, material performance, and regulatory compliance are becoming more significant. Steel and pipe materials, in particular, hold a central role in various applications, from infrastructure projects to residential buildings. By taking the time to evaluate the specific requirements of each project and understanding the characteristics of different steel and pipe types, professionals can make informed decisions that align with their project goals. This guide aims to provide insights into the key considerations when choosing steel and pipe for construction, equipping stakeholders with the knowledge to navigate the complexities of material selection in the modern construction environment.

When selecting steel and pipe for construction projects, it's crucial to understand the various types of steel and their distinct properties. Carbon steel, for example, is widely utilized in construction due to its strength and versatility. It contains carbon as the primary alloying element, which enhances its hardness and strength significantly. Different grades of carbon steel can meet the specific demands of various construction applications, making it essential to choose the right grade for your project requirements.

Stainless steel is another option that is often chosen for its corrosion resistance and aesthetic appeal. This type of steel contains chromium, which forms a protective layer on the surface, preventing rust even in challenging environmental conditions. It is ideal for projects that require durability and a polished finish, such as architectural designs or structures exposed to moisture. Understanding the properties of these different steel types can greatly influence not only the longevity of the structures but also their overall performance, efficiency, and safety in the long run.

| Steel Type | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Applications |

|---|---|---|---|---|

| Mild Steel | 250 | 400 | 20 | Structural applications, general fabrication |

| High Strength Low Alloy Steel | 350 | 550 | 15 | Bridges, heavy equipment |

| Stainless Steel | 210 | 520 | 40 | Corrugated roofing, food processing |

| Tool Steel | 600 | 800 | 5 | Cutting tools, dies |

| Carbon Steel | 300 | 500 | 18 | Pipes, automotive components |

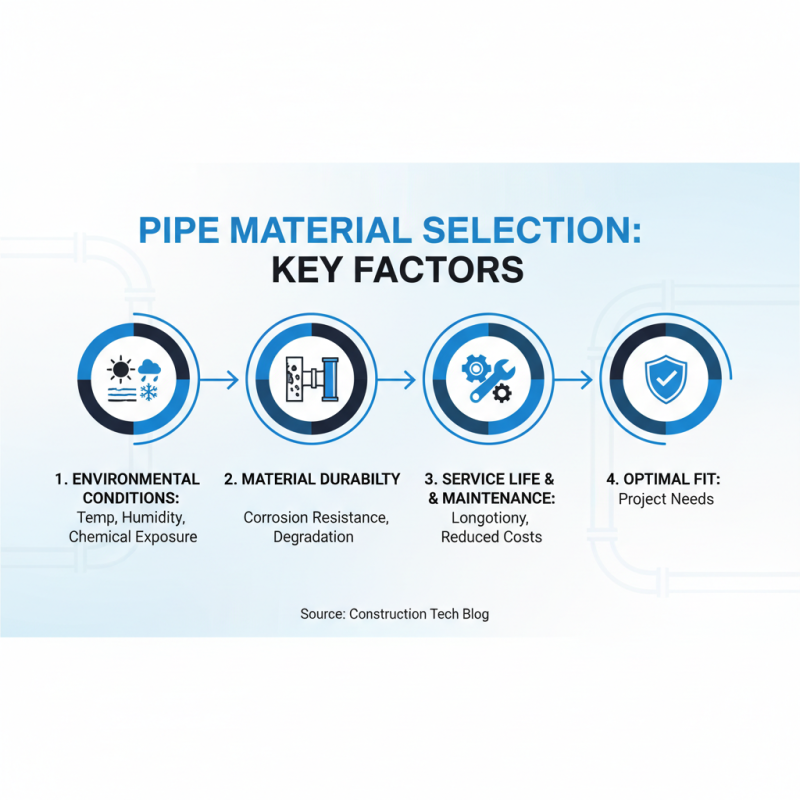

When choosing pipe materials for construction projects, several key factors must be assessed to ensure the best fit for your specific needs. First, consider the environmental conditions the pipes will be exposed to, such as temperature fluctuations, humidity levels, and potential chemical exposure. For instance, certain materials may corrode or degrade faster in harsh environments, necessitating the selection of materials that can withstand these influences for longer service life and reduced maintenance costs.

Another critical factor is the intended application of the pipes. Different construction projects may require various types of pipes, whether for water supply, drainage, or structural support. Understanding the pressure ratings and flow characteristics of the pipe materials is essential for ensuring performance and compliance with safety standards. Additionally, factors such as ease of installation, weight, and compatibility with existing systems can significantly influence material choice, impacting both short-term efficiency and long-term project success.

When selecting the right steel and pipe for construction projects, evaluating strength, durability, and cost is crucial. Strength is often the first criterion that comes to mind, as it directly relates to the structural integrity of a project. The tensile strength and yield strength of the steel play pivotal roles, determining how much load the material can bear before deforming or breaking. For higher load-bearing requirements, opting for steel varieties that provide excellent strength can safeguard against structural failures, ensuring safety and reliability in construction.

Durability is equally important, especially in projects exposed to harsh environmental conditions. Corrosion resistance is a key factor to consider, as it affects the longevity of pipes and structural components. Materials treated with protective coatings or those made from corrosion-resistant alloys can significantly extend the lifespan of construction materials. Furthermore, understanding the impact of environmental factors such as temperature and humidity on steel performance can guide choices that enhance durability.

Lastly, cost remains a fundamental consideration in project planning. While high-strength and durable materials might come with a higher initial investment, analyzing long-term savings from reduced maintenance and replacement costs can yield a more comprehensive financial picture. By balancing these aspects—strength, durability, and cost—construction professionals can make informed decisions that align with their project requirements and budgetary constraints.

Sustainability has become a crucial aspect of steel production, particularly as construction projects in 2025 prioritize eco-friendly practices. The steel industry is evolving to meet these demands through innovative processes that reduce environmental impact. Modern methods include the use of electric arc furnaces that recycle scrap steel, significantly lowering carbon emissions compared to traditional blast furnaces. It is essential for construction professionals to understand these advancements when selecting materials for their projects.

Tips: When assessing steel options, look for products labeled as "green" or from manufacturers that follow sustainable practices. Check for certifications that reflect lower energy consumption and carbon footprint in the production process. Additionally, consider the life cycle of the materials, focusing on their durability and potential for recycling at the end of their use.

Furthermore, the choice of pipe materials should also align with sustainability goals. High-strength steel pipes, designed for longevity, can minimize the need for replacements, thus contributing to a reduction in resource consumption over time.

Tips: When choosing pipes, evaluate their sourcing and production methods. Select suppliers who prioritize eco-friendly practices and transparency in their operations. Engaging with vendors who adhere to sustainability-focused certifications can further ensure that your project aligns with modern environmental standards.

As construction projects evolve, so do the materials used, particularly steel and pipes. In 2025, sustainability and energy efficiency will dominate decision-making processes. Builders will increasingly prefer materials that not only meet stringent environmental standards but also minimize carbon footprints. Manufacturers are expected to innovate greener steelmaking techniques, such as utilizing electric arc furnaces that reduce emissions compared to traditional methods. Furthermore, recycled steel will become a staple, providing both economic and ecological benefits.

In addition to sustainability, advancements in technology will shape the future of steel and pipe selection. Smart materials that self-sensor and provide real-time data on structural integrity will gain traction. This trend will enhance safety and facilitate proactive maintenance. Moreover, the integration of Building Information Modeling (BIM) systems will enable architects and engineers to assess material performance more accurately, which will lead to smarter, more resilient designs. As a result, choosing the right materials will not only be about physical properties but also about aligning with technological advancements and sustainable practices.

"*" indicates required fields