"*" indicates required fields

Choosing the right electrical steel is crucial for your projects. Electrical steel has unique properties that enhance performance in various applications. When selecting it, consider factors like magnetic properties, thickness, and cost.

Different projects demand different types of electrical steel. For instance, some require high permeability. Others might need reduced core losses. Yet, many overlook these specifics, leading to inefficient choices.

Conduct thorough research before making a decision. Analyze the demands of your application carefully. Consider how the selected electrical steel will affect overall efficiency. Each detail counts in creating outstanding results.

Electrical steel is a specialized material designed for electromagnetic applications. It is critical in the manufacturing of transformers, electric motors, and generators. The demand for high-efficiency electrical steel has been rising. Recent reports indicate that the market for electrical steel is projected to grow at a CAGR of 5.6% through 2026.

Understanding the different types of electrical steel is essential. There are two primary categories: silicon-coated and non-oriented electrical steel. The former provides improved efficiency for high-frequency applications. However, it can be more expensive than its counterparts. Non-oriented electrical steel, often used in applications where magnetization is less directional, offers versatility but may compromise efficiency under specific conditions.

Consider the thickness of the steel as well. Thinner gauges can reduce energy loss significantly, but they may also increase production costs. Many manufacturers face challenges when balancing cost and performance. Striving for higher quality comes with its own set of hurdles. Not every project requires the highest grade of electrical steel. It's crucial to evaluate the specific needs of your project carefully.

| Parameter | Description | Value | Application |

|---|---|---|---|

| Electrical Conductivity | Ability of steel to conduct electricity | 5.8 x 10^6 S/m | Transformers |

| Magnetic Permeability | Ease of magnetization of the material | 4000 µ | Electric Motors |

| Core Loss | Energy loss during magnetic cycle | 15 W/kg | Inductors |

| Thickness | Gauge of the electrical steel | 0.35 mm | Power Transformers |

| Si Content | Silicon content in the steel | 3.5% | High Efficiency Motors |

When selecting electrical steel, understanding its magnetic characteristics is crucial. These properties determine how efficiently the steel can conduct magnetic fields. High permeability allows for better magnetic flow, which is essential in applications like transformers and electric motors. However, one must balance permeability with other factors, such as core loss.

Iron loss is another vital consideration. This refers to the energy lost when the material is exposed to changing magnetic fields. Lower iron loss translates to better energy efficiency. However, some types of electrical steel may achieve low iron loss at the expense of other features. A careful selection process is necessary to align project needs with material capabilities.

It’s also important to note that some applications may require sacrifices in one area to excel in another. While you might want low iron loss, high saturation induction is equally significant for certain designs. Finding the right combination can be complex, and often, experimentation is needed. Don’t settle for the first choice; assess multiple steel options before finalizing your decision.

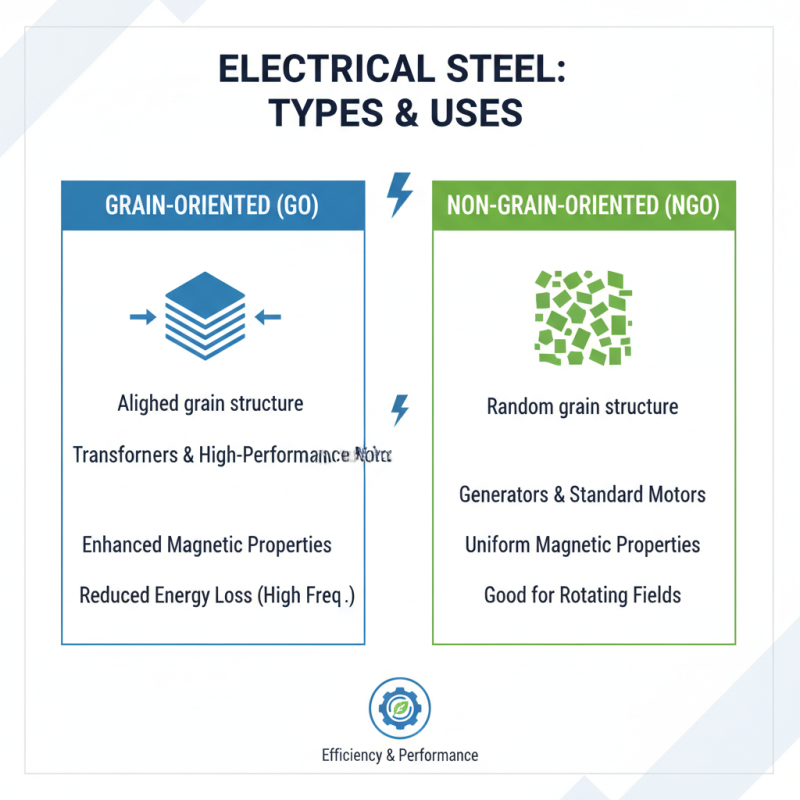

When selecting electrical steel, understanding the two main types is crucial: grain-oriented and non-grain-oriented. Grain-oriented electrical steel is designed to have its grain structure aligned in a specific direction. This alignment enhances performance in transformers and electric motors. The magnetic properties improve significantly, reducing energy losses at high frequencies. Choosing this type often leads to better efficiency in applications requiring high performance.

Non-grain-oriented electrical steel has a more random grain structure. It is versatile and works well in various applications, like appliances and general motors. While its magnetic performance is not as high as that of grain-oriented steel, it offers flexibility. This can be beneficial in designs where space or manufacturing constraints exist. However, it may lead to slightly higher energy losses when compared to its oriented counterpart.

It's essential to reflect on your project needs. Do you prioritize efficiency or versatility? Consider the specific performance requirements and cost implications. Sometimes, a choice isn’t clear-cut. Ensure to assess both options against real-world applications. Making a well-informed choice can lead to improved project outcomes.

Choosing the right electrical steel for a project involves several crucial factors. The magnetic properties of the steel are vital. High permeability and low core loss are desirable features. Evaluate these specifications based on the project's requirements. Understanding these elements can be challenging. Not every steel option meets the required standards.

Additionally, the thickness of the electrical steel plays a significant role. Thinner laminations reduce energy losses but can be costly. Consider your budget and available resources. The manufacturing process also affects performance. Some processes yield better magnetic characteristics than others. Research and understand these processes.

Finally, environmental conditions must not be overlooked. High humidity can corrode some metals. Choose a steel that suits your environment. This often requires additional testing. It is essential to reflect on these parameters. A small oversight can lead to significant project failures. Balancing performance and cost is crucial for success.

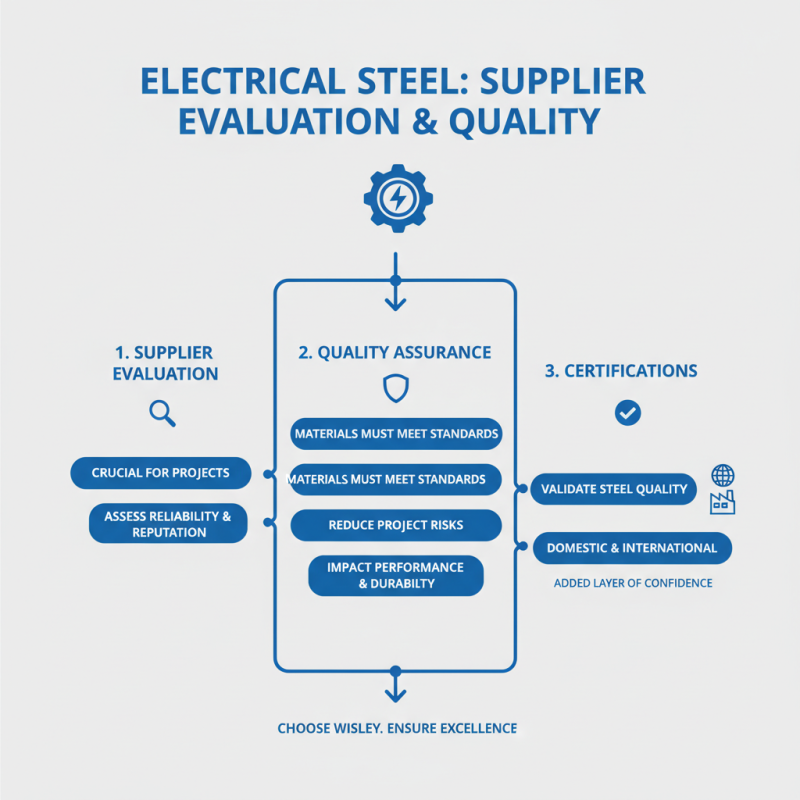

When choosing electrical steel for your projects, supplier evaluation is crucial. Quality assurance plays a key role. Make sure the materials offered by your suppliers meet industry standards. Look for certifications that validate the quality of the steel. This includes both domestic and international certifications. They provide an added layer of assurance.

Not all suppliers are equal. Some may claim high quality but lack proper documentation. Ask them for their quality control processes. A reputable supplier should be willing to share this information. This transparency helps build trust. However, some suppliers might hesitate, raising red flags. Pay attention to these signals during your evaluation.

Consider the specific applications of the electrical steel. Different projects may require different grades or treatments. Not all suppliers will have the exact specifications you need. It’s important to communicate your project requirements clearly. This clarity helps both you and the supplier align your expectations. Reflect on past supplier experiences, as they can inform your future choices. Choosing wisely can impact project success and long-term relationships.

"*" indicates required fields