"*" indicates required fields

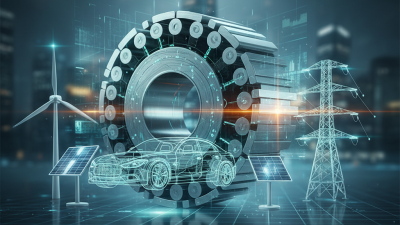

In the realm of modern technology, aluminum electrical components play a pivotal role. Renowned expert Dr. Emily Thompson, a leading figure in materials engineering, states, "Aluminum electrical parts enable the performance of our devices while minimizing weight." These components are critical in industries such as telecommunications, automotive, and renewable energy.

Aluminum electrical solutions provide excellent conductivity and corrosion resistance. They make devices lighter and easier to integrate. This is increasingly essential as technology becomes more compact and efficient. As we push the limits of innovation, a careful assessment of these materials becomes necessary.

However, there is still room for improvement in their sustainability. Some manufacturing processes leave a larger carbon footprint. It’s a reminder that while aluminum electrical components are vital, we must seek better methods. Balancing efficiency with environmental responsibility is a challenge that the industry must navigate.

Aluminum plays a crucial role in modern electrical components. Its lightweight nature keeps devices portable. This is especially important in electronics like smartphones and laptops. These devices benefit from using aluminum for their enclosures, reducing the overall weight. Besides portability, aluminum offers excellent thermal conductivity. It helps dissipate heat effectively, preventing overheating in high-performance components.

Moreover, aluminum's resistance to corrosion enhances the durability of electrical parts. This is vital in various environments, from humid climates to industrial settings. However, the production of aluminum can be energy-intensive, raising concerns about environmental impact. There are ongoing efforts to find more sustainable methods for aluminum production. Reducing this impact could make aluminum an even better choice for the technology of the future.

In addition, while aluminum is affordable, there are performance trade-offs. For instance, its conductivity is lower than copper's. This requires careful engineering to ensure efficiency in circuits. Despite these challenges, the versatility of aluminum continues to drive innovation in electrical design. Balancing its benefits and drawbacks will be essential as technology evolves.

Aluminum is a critical material in modern electronics. Its lightweight nature and excellent conductivity make it a prime choice for electrical components. According to a recent industry report, over 70% of electronic devices utilize aluminum elements. This statistic highlights aluminum's significance in technology.

One major advantage of aluminum is its cost-effectiveness. It is often cheaper than copper, the usual go-to conductor. Aluminum can reduce the overall production costs for manufacturers. This savings can be passed on to consumers, making devices more affordable. Plus, aluminum is abundant, with a recycling rate of about 75%. This sustainability reduces environmental impact.

Tips: When designing electronics, consider aluminum for a balance of performance and cost. It’s worth assessing the weight-benefit ratio for portable devices. However, remember that aluminum can have some limitations. Its strength can be lower than copper, which may affect some applications.

In addition to economic benefits, aluminum resists corrosion, prolonging component life. This is crucial in harsh environments. Effective thermal management is another advantage, as aluminum dissipates heat effectively. Thus, it aids in maintaining device performance and longevity. However, it’s essential to be cautious of its mechanical properties during high-stress applications.

Aluminum plays a crucial role in enhancing electrical conductivity and efficiency. Its lightweight nature makes it an ideal choice for various applications. Studies show that aluminum can conduct electricity at approximately 61% of copper's efficiency. However, it is nearly one-third the weight of copper, which significantly reduces material costs in larger installations.

In recent research, it has been found that using aluminum components can cut down energy loss during transmission. In high-voltage power lines, aluminum conductors reduce energy loss by about 20%. This improvement is essential for modern technology, helping to minimize carbon footprints. Still, some challenges remain. Aluminum is prone to oxidation, which can impact long-term conductivity.

Repairing or replacing oxidized connections can be costly and time-consuming. Despite these drawbacks, the benefits of aluminum often outweigh the negatives. The industry continues to innovate, finding ways to enhance aluminum's performance. Techniques such as improved coating methods are being explored to counteract oxidation. Overall, aluminum's significance in electrical components cannot be overlooked, even as its limitations require ongoing attention.

Aluminum electrical components play a pivotal role across various industries. In automotive applications, lightweight aluminum aids in improving fuel efficiency. According to a recent study, vehicles with aluminum components can achieve up to 25% weight reduction. This reduction enhances performance and lowers emissions.

In the aerospace sector, aluminum is crucial for reducing the overall weight of aircraft. The weight savings translate to lower fuel consumption. The International Air Transport Association (IATA) reports that every kilogram saved can reduce fuel costs by up to $20,000 annually per aircraft. These figures highlight the financial and environmental benefits of aluminum.

However, it's important to consider the recycling of aluminum. While it's highly recyclable, only about 75% of aluminum produced is still in use today. Enhancing recycling rates can further benefit the environment. Some industry experts argue that more awareness is needed. Overall, the role of aluminum components must evolve to meet modern demands sustainably.

The future of technology is increasingly tied to the use of aluminum electrical components. According to industry reports, the global aluminum market for electrical applications is expected to reach $200 billion by 2027. This growth is driven by aluminum's lightweight and corrosion-resistant properties, making it ideal for various applications.

Aluminum's thermal conductivity is crucial for efficient energy transfer. More devices now require lightweight materials for better performance. For example, electric vehicles (EVs) are benefiting significantly from aluminum components. These parts help reduce weight, increasing energy efficiency. A 2022 study shows that aluminum can reduce vehicle weight by up to 50%. However, the industry must address the environmental impacts of aluminum production.

Tips: Consider using aluminum in projects where weight and conductivity matter. Its widespread use can lead to substantial energy savings. However, reflect on the sustainability practices within the aluminum supply chain as you move forward. The balance between performance and environmental responsibility is vital for future innovations.

"*" indicates required fields