"*" indicates required fields

In the dynamic world of manufacturing, aluminum pipes play a pivotal role across various industries. According to Dr. Emily Carter, a leading expert in materials science, "Aluminum pipes are transforming the way we think about lightweight and durable solutions." Innovations in aluminum pipe applications are on the rise, offering improved efficiency and sustainability.

The versatility of aluminum pipes has led to their adoption in aerospace, automotive, and construction sectors. These applications highlight their strength and resistance to corrosion. Companies strive to integrate advanced technologies, such as 3D printing and alloy developments, making aluminum pipes even more effective. However, some challenges remain, including cost and manufacturing limitations.

As we delve into the future of aluminum pipes in 2026, it is essential to reflect on these ongoing innovations and their impact. Understanding the balance between technological advancement and practical usability will shape the direction of this industry. The next few years could redefine traditional applications, enhancing both performance and environmental responsibility.

In 2026, aluminum pipes are expected to play a crucial role in various industries. The demand for lightweight materials continues to rise. This trend is evident in the automotive and aerospace sectors. Manufacturers will focus on durable yet malleable aluminum pipes. These materials contribute to fuel efficiency and lower emissions.

In construction, aluminum pipes will become more popular. They offer excellent corrosion resistance and long lifespan. Companies will increasingly turn to aluminum for plumbing and HVAC systems. This shift might lead to better building standards. However, the sustainability of aluminum production raises questions.

Tips: Always consider the recycling potential of materials. Ensure you choose suppliers who prioritize eco-friendly practices. Innovations in alloy technology may offer new properties yet come with challenges too. Experimentation may reveal unexpected benefits or drawbacks in usage.

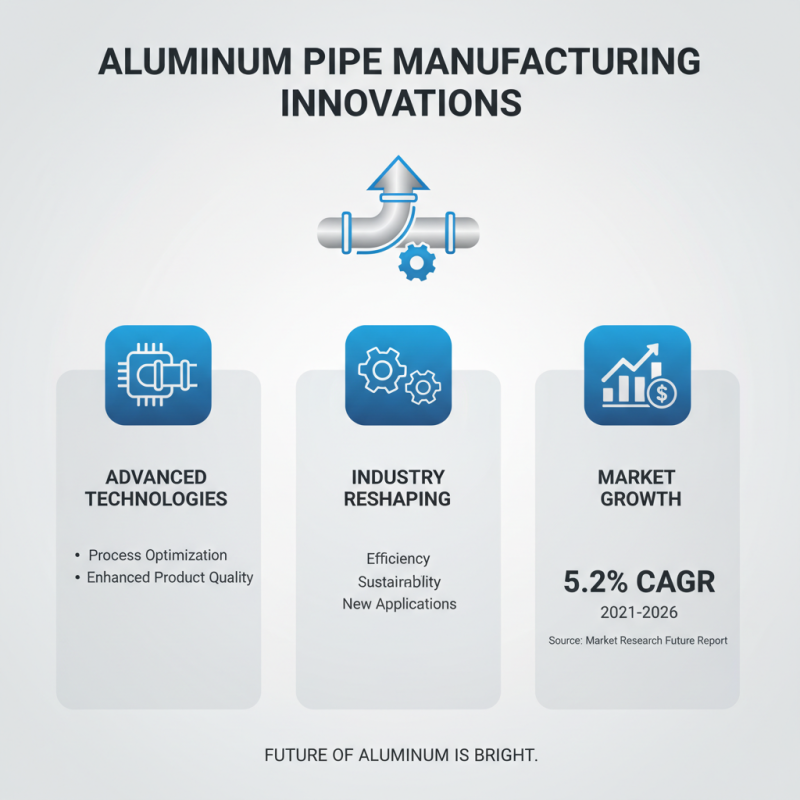

Innovations in aluminum pipe manufacturing are reshaping the industry. Advanced technologies are optimizing processes and enhancing product quality. A report by Market Research Future indicates that the aluminum pipe market is expected to grow at a CAGR of 5.2% from 2021 to 2026.

Automation plays a crucial role. Robotics streamline welding and assembly, reducing labor costs and time. This adaptation leads to a 30% increase in efficiency. Smart sensors monitor production lines, instantly identifying defects. This real-time data analysis mitigates waste, saving resources.

Additive manufacturing is becoming popular. It allows for producing complex aluminum structures with reduced material usage. Studies show that this can cut costs by up to 25%. However, challenges remain. Implementing these technologies requires significant investment and skilled labor. Not all companies can adapt quickly to these innovations. The gap between early adopters and those lagging behind is widening.

The aluminum pipe industry is undergoing significant changes, driven by sustainability trends. Eco-friendly practices are becoming a priority. Manufacturers are looking for ways to reduce energy consumption in production. Innovations in recycling processes are also on the rise. These efforts not only improve material efficiency but also lessen environmental impacts.

Aluminum is widely regarded for its lightweight and corrosion-resistant properties. However, its production is energy-intensive. Recent advances aim to address this issue. One emerging method uses renewable energy sources for smelting. Another approach emphasizes closed-loop recycling systems. Such systems minimize waste and enhance overall sustainability. But challenges remain. Not all facilities have access to renewable options yet.

The push for sustainability also affects product design. Companies are exploring innovative designs that require less material. This can lead to lighter, stronger aluminum pipes. However, results can vary. Not all new products meet performance expectations. Finding the right balance between sustainability and functionality is crucial. Industry players need continuous feedback to improve their processes.

The construction and infrastructure sectors are rapidly adopting aluminum pipes. Lightweight yet strong, aluminum pipes are ideal for various applications. According to a recent industry report, the market for aluminum pipes is projected to grow by 5.8% annually through 2026. This growth is fueled by the need for more efficient materials in engineering solutions.

Aluminum pipes are increasingly being used in structural support and fluid transportation systems. They offer corrosion resistance, which prolongs service life. In areas prone to extreme weather, such durable materials are essential. However, the industry still faces challenges. Sourcing high-quality aluminum remains a concern for manufacturers. There is also ongoing debate about recyclability. While aluminum is widely recyclable, not all systems ensure proper recycling practices.

Moreover, the integration of aluminum pipes in new smart infrastructure projects shows potential. A study highlighted that using aluminum can reduce the overall weight of constructions, leading to lower transportation costs. Yet, the industry's reliance on aluminum must be balanced with environmental impacts. Sustainable practices are still evolving, necessitating further exploration and adaptation.

The aluminum pipe market faces both challenges and opportunities in the coming years. According to a recent report, the demand for aluminum pipes is projected to grow at a CAGR of 5.8% from 2023 to 2028. Industries like construction and automotive are major drivers. However, fluctuating raw material costs pose a significant challenge. This volatility can lead to pricing uncertainties. Manufacturers must stabilize their supply chains to mitigate risks.

Sustainability is another critical area for development. More industries are seeking eco-friendly solutions. Aluminum pipes can be recycled, which reduces their carbon footprint. Yet, many companies still struggle with implementing sustainable practices effectively. They need to invest more in advanced recycling technologies. This shift could provide a competitive edge.

Innovation is vital for the future of aluminum pipes. Emerging technologies like 3D printing offer exciting possibilities. However, they also require a skilled workforce, which is currently lacking. Bridging this skill gap is crucial for industry growth. The path forward is filled with potential, but it requires introspection and strategic planning from all parties involved.

| Application Area | Current Innovations | Market Challenges | Future Opportunities |

|---|---|---|---|

| Automotive | Lightweight aluminum alloys | Regulatory pressures for emissions | Growth in electric vehicles |

| Construction | Aluminum scaffolding systems | Cost of raw materials | Sustainable building practices |

| Aerospace | Advanced aluminum composites | Stringent safety regulations | Increased demand for fuel efficiency |

| Marine | Corrosion-resistant aluminum pipes | Impact of climate change | Expansion of leisure boating |

| HVAC | Aluminum heat exchangers | Energy efficiency mandates | Smart HVAC technology integrations |

"*" indicates required fields